Dawb qauv rau Tuam Tshoj ASTM A53 / BS1387 Threaded thiab Coupled Kub Dipped Galvanized Steel Yeeb Nkab

Txheej txheem cej luam

Txhua tus tswv cuab los ntawm peb cov neeg ua haujlwm tau txais txiaj ntsig loj ua rau muaj txiaj ntsig rau cov neeg siv khoom xav tau thiab koom haum sib txuas lus rau ASTM A53 / BS1387 Kub Dipped Galvanized Steel Pipe. Vam tias peb tuaj yeem yog koj tus neeg muag khoom ntseeg siab hauv Suav teb. Nrhiav rau pem hauv ntej rau koj txoj kev koom tes .Nrog ntau tshaj 9 xyoo ntawm kev paub thiab ib pab neeg ua haujlwm, peb tau xa peb cov khoom mus rau ntau lub teb chaws thiab cheeb tsam thoob plaws ntiaj teb. Peb zoo siab tos txais cov neeg siv khoom, cov koom haum ua lag luam thiab cov phooj ywg los ntawm txhua qhov chaw hauv ntiaj teb los tiv tauj peb thiab nrhiav kev koom tes rau kev sib nrig sib pab.

Kub-dip galvanizing muaj qhov zoo ntawm txheej txheej, muaj zog adhesion thiab lub neej ua haujlwm ntev. Cov teeb meem ntawm lub cev thiab tshuaj lom neeg tshwm sim ntawm cov yeeb nkab steel matrix thiab molten plating tov los tsim cov txheej txheem corrosion-resistant zinc-hlau alloy nrog cov qauv compact. Cov txheej txheej alloy yog kev sib xyaw nrog cov zinc txheej ntshiab thiab cov yeeb nkab steel matrix. Yog li ntawd, nws cov corrosion kuj muaj zog.

Yuav tsum nco ntsoov tias xyoo 1960 thiab 1970, cov teb chaws tsim kho hauv ntiaj teb tau pib tsim cov kav dej tshiab thiab maj mam txwv cov kav dej galvanized. Plaub lub tuam tsev haujlwm thiab cov thawj coj suav nrog Ministry of Construction ntawm Tuam Tshoj kuj tau tshaj tawm cov ntaub ntawv qhia meej tias cov kav dej galvanized tau raug txwv los ntawm 2000 mus txog rau. Cov kav dej galvanized tsis tshua siv rau cov kav dej txias hauv cov zej zog tshiab, thiab cov kav dej galvanized yog siv rau cov kav dej kub hauv qee cov zej zog.

Daim ntawv thov

Nws yog siv rau kev quab yuam thiab qhov siab, thiab rau lub hom phiaj dav dav, dej, roj thiab cov kav dej.

Qib tseem ceeb

GR.A, IB

Chemical Component

| Qib | Cov ntsiab lus %, ≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| S hom (seamless yeeb nkab) | |||||||||

| GR.A | 0.25B | 0.95 ib | 0.05 Nws | 0.045 ib | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

| GR.B | 0.30 NwsC | 1.20 | 0.05 Nws | 0.045 ib | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

| E hom (Resistance welded yeeb nkab) | |||||||||

| GR.A | 0.25B | 0.95 ib | 0.05 Nws | 0.045 ib | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

| GR.B | 0.30 NwsC | 1.20 | 0.05 Nws | 0.045 ib | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

| F hom (Qhov cub Welded yeeb nkab) | |||||||||

| A | 0.30 NwsB | 1.20 | 0.05 Nws | 0.045 ib | 0.40 Nws | 0.40 Nws | 0.40 Nws | 0.15 | 0.08 ib |

A Tus lej ntawm tsib lub ntsiab lus no yuav tsum tsis txhob ntau tshaj 1.00%.

B Rau txhua txhua 0.01% txo qis hauv cov ntsiab lus siab tshaj plaws, qhov siab tshaj plaws manganese cov ntsiab lus tau tso cai kom nce 0.06%, tab sis qhov siab tshaj plaws tsis tuaj yeem tshaj 1.35%.

C Txhua 0.01% txo qis hauv cov ntsiab lus siab tshaj plaws yuav tso cai rau cov ntsiab lus manganese siab tshaj plaws kom nce 0.06%, tab sis qhov siab tshaj plaws yuav tsum tsis pub tshaj 1.65%.

Mechanical Property

| yam khoom | GR.A | GR.B |

| tensile zog, ≥, psi [MPa] Yield zog, ≥, psi [MPa] Gauge 2in.or 50mm elongation | 48 000 [330] 30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Qhov tsawg kawg nkaus elongation ntawm gauge ntev 2in. (50mm) yuav tsum tau txiav txim los ntawm cov qauv hauv qab no:

e=625000(1940)A0.2/U0.9

e = qhov tsawg kawg nkaus elongation ntawm lub ntsuas 2in. (50mm), qhov feem pua tawm mus rau qhov ze tshaj 0.5%;

A = Muab xam raws li cov txheej txheem sab nraud ntawm lub nominal raj los yog lub nominal dav ntawm cov qauv tensile thiab nws cov phab ntsa thickness, thiab sib npaug mus rau qhov ze tshaj plaws cross-sectional cheeb tsam ntawm lub tensile qauv ntawm 0.01 in.2 (1 mm2), thiab Nws muab piv nrog 0.75in.2 (500mm2), qhov twg me dua.

U = teev tsawg kawg nkaus tensile zog, psi (MPa).

B Rau ntau qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txawv ntawm qhov ntsuas tensile thiab cov txheej txheem tensile yam tsawg kawg nkaus, qhov tsawg kawg nkaus elongation yuav tsum tau qhia hauv Table X4.1 lossis Table X4.2, raws li nws qhov kev siv tau.

Kev Xeem Xeem

Tensile test, dabtsi yog khoov test, hydrostatic test, nondestructive hluav taws xob kuaj ntawm welds.

Muaj peev xwm muab khoom

Muaj peev xwm muab khoom: 2000 Tons Ib Hlis Ib Qib Ntawm ASTM A53 / A53M-2012 Hlau Yeeb Nkab

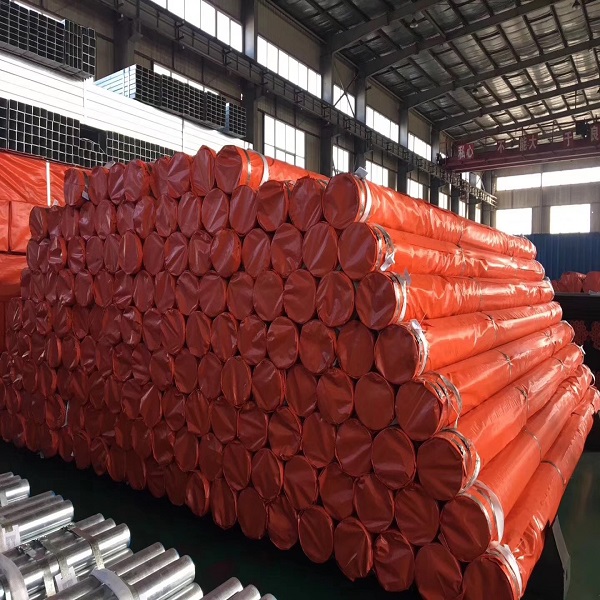

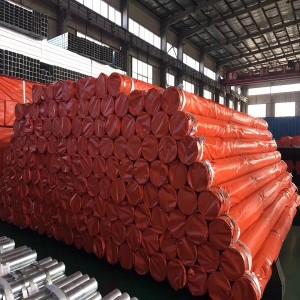

Ntim

Nyob rau hauv Bundles Thiab Nyob rau hauv lub zog ntoo thawv

Kev xa khoom

7-14 hnub yog nyob rau hauv Tshuag, 30-45 hnub los tsim

Kev them nyiaj

30% tso nyiaj, 70% L / C lossis B / L daim ntawv lossis 100% L / C thaum pom