Shiinaha Brand Cusub Q235C Q235B 16Mn tuubo bir ah oo kaarboon alxan leh

Dulmar

Shirkaddu waxay taageertaa falsafada ah "Noqo midka ugu sarreeya ee ku saabsan xalka tuubada", waxaan sii wadi doonnaa inaan u adeegno macmiishii hore iyo kuwa cusub ee guriga iyo dibaddaba si kulul. Birta kaarboonka ee alxanka leh ama tuubada aan sinnayn ee raacaysa heerka ASTM A53, waxaanu leenahay waayo-aragnimo 30 sano ka badan si aan wax u gadano, taas oo dammaanad qaadi karta inaanu awood u yeelano inaanu hubino inay tuubooyin kasta tayadoodu sarrayso.

Ku saabsan tuubooyin aan fiicneyn, waxaa jira tuubo aan fiicneyn oo been abuur ah, taas oo hantida farsamada ay ka hooseyso tuubada aan cillad lahayn, sababtoo ah waxay ka samaysan tahay tuubada ERW, ka dib habka, xariiqda alxanka ayaa isu beddelay mid aan la arki karin. Dhuumaha noocaan ah ma qaadi karaan cadaadis sare, iyo xoogga xajinta, walbahaarka gudaha oo dhan ma buuxin karaan shuruudaha ku saabsan tuubada aan cillad lahayn. Haddii ay dhacdo in la isku daro labadan tuubooyin noocaan ah, fadlan ogow in tuubada ERW oo dhan laga sameeyay xariijimaha birta, sidaa darteed waxay leedahay dhumuc darbi ah oo isku mid ah; Dhuumaha aan kala go 'lahayn waxaa laga sameeyaa bar wareegsan, dalool bartamaha bar wareega si ay u sameeyaan tuubooyinka, si dhumucdiisuna derbiga ma aha labis. Iyo xariiqda alxanka ee tuubooyin been abuur ah ayaa wali jira, haddii aad si taxadar leh u hubiso tuubada gudaha, waad heli kartaa.

Waxaa inta badan loo isticmaalaa qaybaha xoogga iyo cadaadiska, iyo ujeedada guud uumiga, biyaha, gaaska iyo tuubooyinka hawada.

Fasalka ugu weyn

GR.A, GR.B

Qayb Kiimiko ah

| Darajo | Qayb%,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Nooca S (tuubo aan toos ahayn) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca E (tuubo alxanka iska caabin ah) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca F (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Wadarta shantan curiye waa in aanay ka badnaan 1.00%.

B 0.01% kasta oo hoos u dhaca kaarboonka ugu badan, waxa ku jira manganese ugu badnaan waxa loo ogolyahay in uu kordho 0.06%, laakiin ugu badnaan kama badnaan karo 1.35%.

C 0.01% kasta oo hoos u dhaca kaarboonka ugu badan wuxuu u oggolaanayaa ugu badnaan maadada manganese inay korodho 0.06%, laakiin ugu badnaan waa inaanu ka badnayn 1.65%.

Hantida Makaanikada

| shayga | GR.A | GR.B |

| xoogga xajinta, ≥, psi [MPa] Xoogga Wax-soo-saarka, ≥, psi [MPa] Qiyaas 2in.ama 50mm elongation | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Kordhinta ugu yar ee dhererka cabbirka 2in. (50mm) waa in lagu go'aamiyaa qaacidooyinka soo socda:

e=625000(1940)A0.2/U0.9

e = dhererka ugu yar ee cabbirka 2in. (50mm), boqolkiiba waxa lagu soo koobay 0.5% ee ugu dhow;

A = Waxaa la xisaabiyaa iyadoo loo eegayo dhexroorka bannaanka ee la cayimay ee tuubada magaca ama ballaca magaca ee muunadda xajinta iyo dhumucdeeda darbi ee la cayimay, oo lagu soo koobay qaybta ugu dhow ee muunadda xajinta ee 0.01 in.2 (1 mm2), waxaana la barbar dhigayaa 0.75in.2 (500mm2), hadba kii ka yar.

U = la cayimay xoogga xajinta ugu yar, psi (MPa).

B Isku-darka kala duwan ee cabbirrada kala duwan ee shaybaarrada tijaabada xajinta iyo xoogga ugu yar ee la qoray, dhererka ugu yar ee loo baahan yahay ayaa lagu muujiyey Shaxda X4.1 ama Shaxda X4.2, iyadoo loo eegayo ku habboonaanteeda.

Shuruudaha Imtixaanka

Tijaabada xamaasadda, tijaabada foorarsiga, tijaabada hydrostatic, tijaabada korantada ee alxanka oo aan burbursanayn.

Awood-siinta

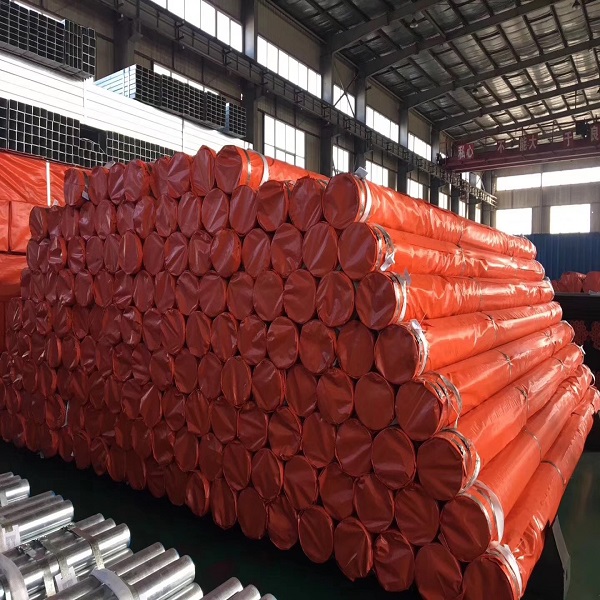

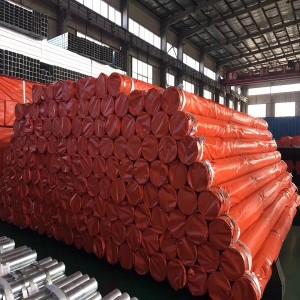

Awooda Sahayda: 2000 Ton bishiiba Fasalka ASTM A53/A53M-2012 Dhuumaha Bir

Baakadaha

Xirmooyinka iyo Sanduuqa Alwaaxda ee Xoogan

gaarsiin

7-14 maalmood haddii kaydka, 30-45 maalmood si loo soo saaro

Lacag bixinta

30% deebaaji, 70% L/C ama nuqul B/L ama 100% L/C marka la eego