Umzi-mveliso waseTshayina oPhezulu oPhakamileyo oLungileyo weCarbon Steel Welded imibhobho

Isishwankathelo

"Lawula umgangatho ngeenkcukacha, bonisa amandla ngomgangatho". Ishishini lethu lizamile ukuseka abasebenzi abasebenzayo nabazinzileyo kwaye baphonononga inkqubo esebenzayo yokulawula umgangatho weStraight Carbon Steel Welded Pipes. Umgangatho olungileyo bubukho bomzi-mveliso, kugxilwe kwimfuno yomthengi ngumthombo wokusinda kunye nenkqubela phambili yenkampani, Sithobela ukunyaniseka kunye nesimo sengqondo esisebenzayo sokholo, ukuzingela phambili ekuzeni kwakho!

Ngombhobho we-carbon steel welded, kukho i-2 iteknoloji ebalulekileyo ekufuneka iqaphele ukuba yi-ERW (i-electric resistance weld) kunye ne-SAW (i-submerge arc weld). Imibhobho esetyenzisiweyo kobu buchwepheshe zombini isetyenziselwa ushishino lwepetroleum kuthutho lweoyile negesi, kodwa zonke zinenzuzo yazo, ngoko ke ukusetyenziswa luhlobo olwahlukileyo.

Umbhobho we-ERW wenziwe ngepleyiti yentsimbi, kukho umthungo omnye kuphela odityanisiweyo, kwaye ngenxa yokuba umgca odityanisiweyo wombhobho we-ERW uvela kumbhobho ongumama, awudingi solder flux, ngoko ke ipropathi yomatshini ilungile. Kwaye ngenxa yeempawu zayo zokusebenza kakuhle kwemveliso, ixabiso eliphantsi, ukugcinwa kwezinto, kunye nokuzenzekelayo, thelekisa kunye nombhobho we-SAW, umbhobho we-ERW ngumbhobho wentsimbi kunye nokusebenza kwemveliso ephezulu, umgangatho ohamba phambili kunye nokusebenza ngokoqoqosho kwintsimi ye-oyile kunye nokugcinwa kwegesi. kunye nezothutho. Ngokukodwa landela ukukhula kobuchwepheshe, umgangatho ukuba umgca we-welding ungcono ngakumbi nangakumbi, ngokusebenzisa iteknoloji entsha, injongo kukuphelisa uxinzelelo, ukuthambisa kunye nokucokisa isakhiwo, kunye nokuphucula iimpawu zoomatshini ezibanzi zendawo echaphazelekayo yokushisa. Olu hlobo lombhobho we-ERW alukwazi ukuhlukaniswa kuphela, kodwa kunye ne-weld coefficient ifikelela kwi-1, eqonda ukuhambelana kwesakhiwo sendawo ye-weld kunye nezinto ezisisiseko.

Ubuninzi betekhnoloji yeSAW buphezulu kakhulu, kwaye umaleko we-flux uthintela ukulahleka kobushushu okukhawulezayo kwaye ugxininise kwindawo yokuthambisa. I-arc welding ephantsi kwamanzi inomgangatho ophezulu we-weld seam, ukusebenza kakuhle kwemveliso, akukho kukhanya kwe-arc kunye nomsi omncinci. Imibhobho yentsimbi edibeneyo ye-arc edibeneyo isetyenziswa ngokubanzi kwiinqanawa zoxinzelelo, ukufakwa kwemibhobho, imiqadi, iikholamu, i-low-pressure fluids, kunye neeprojekthi zesakhiwo sentsimbi. Kodwa kwishishini lepetroleum yelizwe eliphuhlileyo, umbhobho we-SAW awuvumelekanga ukuba ungene kuba umda ngokwawo, kuphela eTshayina umbhobho we-SAW usavunyelwe kushishino lwepetroleum ngomda.

Umgangatho olungileyo kunye nexabiso elifanelekileyo "yimigaqo yethu yoshishino. Ukuba unomdla kwiimveliso zethu kunye nezisombululo okanye unayo nayiphi na imibuzo, qiniseka ukuba uziva ukhululekile ukuqhagamshelana nathi. Sinethemba lokuseka ubudlelwane bentsebenziswano kunye nawe kungekudala.

Isicelo

Isetyenziswa ikakhulu kumandla kunye noxinzelelo lwamalungu, kunye nenjongo eqhelekileyo yomphunga, amanzi, igesi kunye nemibhobho yomoya.

IBanga eliPhambili

G.A, GR.B

ICandelo leMichiza

| IBanga | Icandelo %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (umbhobho ongenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (umbhobho wokuchasa odityanisiweyo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-F | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isimbuku sezi elementi zintlanu masingabi ngaphezu kwe-1.00%.

B Ngayo yonke i-0.01% yehla kwi-carbon content, umxholo we-manganese ophezulu uvumelekile ukuba unyuke ngo-0.06%, kodwa ubuninzi abukwazi ukudlula i-1.35%.

C Ukuncipha ngakunye kwe-0.01% kowona mxholo wekhabhoni uphezulu kuya kuvumela owona mxholo uphezulu wemanganese ukuba unyuke nge-0.06%, kodwa ubuninzi bungagqithi kwi-1.65%.

IPropati yoomatshini

| into | G.A | GR.B |

| amandla okuqina, ≥, psi [MPa] Amandla eSivuno, ≥, psi [MPa] Igeyiji 2in.okanye 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubuncinane bobude begeyiji yobude obuyi-2in. (50mm) iya kumiselwa ngale fomula ilandelayo:

e=625000(1940)A0.2/U0.9

e = ubuncinane bobude begeyiji 2in. (50mm), ipesenti isondezwe kweyona 0.5% ikufutshane;

A = Kubalwa ngokwe-diameter yangaphandle echaziweyo yetyhubhu yegama okanye ububanzi begama lesampulu ye-tensile kunye nobukhulu bayo obuchaziweyo bodonga, kwaye ijikelezwe kwindawo ekufutshane ye-cross-sectional ye-tensile yesampuli ye-0.01 in.2 (1 mm2), kwaye Ithelekiswa ne-0.75in.2 (500mm2), nokuba yeyiphi encinci.

U = ubuncinci bamandla okuqina, i-psi (MPa).

B Kwiindibaniselwano ezahlukeneyo zobukhulu obahlukeneyo besampulu zovavanyo lwe-tensile kunye namandla amiselweyo amiselweyo, ubuncinane bobude obufunekayo buboniswa kwiTheyibhile X4.1 okanye kwiTheyibhile X4.2, ngokokusebenza kwayo.

Imfuneko yoVavanyo

Uvavanyo lwe-tensile, uvavanyo lokugoba, uvavanyo lwe-hydrostatic, uvavanyo lombane olungonakalisiyo lwe-welds.

Supply Ability

Amandla okubonelela: IiToni ezingama-2000 ngeNyanga ngeBanga ngalinye le-ASTM A53/A53M-2012 iPipe yentsimbi

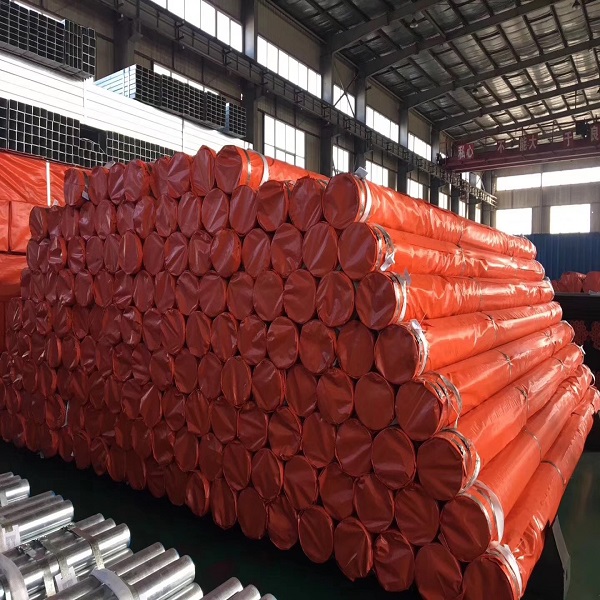

Ukupakishwa

Kwimiyanda kunye nakwiBhokisi yoMthi eyomeleleyo

Ukuhanjiswa

7-14 iintsuku ukuba isitokhwe, 30-45 iintsuku ukuvelisa

Intlawulo

30% idepsoit, 70% L/C okanye B/L ikopi okanye 100% L/C ngokubona