Isampulu yasimahla ye China ASTM A53/BS1387 Umbhobho weNtsimbi oDitshweyo oDitshweyo

Isishwankathelo

Ilungu ngalinye elivela kwiqela lethu lengeniso yentsebenzo enkulu lixabisa iimfuno zabathengi kunye nonxibelelwano lombutho lwe-ASTM A53/BS1387 Umbhobho weNtsimbi oDidiweyo oshushu oDitshweyo. Ndiyathemba ukuba singaba ngumthengisi wakho othembekileyo eTshayina. Sijonge phambili intsebenziswano yakho .Ngamava angaphezu kwe-9 kunye neqela leengcali, siye sathumela iimveliso zethu kumazwe amaninzi nakwimimandla yehlabathi jikelele. Samkela abathengi, imibutho yamashishini kunye nabahlobo abavela kuzo zonke iindawo zehlabathi ukuba baqhagamshelane nathi kwaye bafune intsebenziswano ukuze bafumane inzuzo efanayo.

I-Hot-dip galvanizing ineenzuzo zokugquma okufanayo, ukubambelela okuqinileyo kunye nobomi obude benkonzo. Ubunzima bomzimba kunye neekhemikhali zenzeke phakathi kwe-matrix yombhobho wentsimbi kunye nesisombululo se-plating esityhidiweyo ukwenza i-corrosion-resistant zinc-iron alloy layer kunye nesakhiwo esihlangeneyo. Uluhlu lwe-alloy luhlanganiswe kunye ne-zinc ecocekileyo kunye ne-matrix yombhobho wensimbi. Ngoko ke, ukuxhathisa kwayo kunamandla.

Kufuneka kuqatshelwe ukuba i-1960 kunye ne-1970s, amazwe aphuhlileyo emhlabeni aqala ukuphuhlisa iintlobo ezintsha zemibhobho kwaye ngokuthe ngcembe avala imibhobho ye-galvanized. Abaphathiswa abane kunye neekomishoni ezibandakanya i-Ofisi yoLwakhiwo lwase-China bakhuphe uxwebhu olucacisa ukuba imibhobho ye-galvanized iye yavalwa ukusuka kwi-2000 ukuya phambili. Imibhobho enezinki ayifane isetyenziswe kwimibhobho yamanzi abandayo kwiindawo ezisanda kwakhiwa, kwaye imibhobho enamazinki isetyenziselwa imibhobho yamanzi ashushu kwezinye iindawo.

Isicelo

Isetyenziswa ikakhulu kumandla kunye noxinzelelo lwamalungu, kunye nenjongo eqhelekileyo yomphunga, amanzi, igesi kunye nemibhobho yomoya.

IBanga eliPhambili

G.A, GR.B

ICandelo leMichiza

| IBanga | Icandelo %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (umbhobho ongenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (umbhobho wokuchasa odityanisiweyo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-F | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isimbuku sezi elementi zintlanu masingabi ngaphezu kwe-1.00%.

B Ngayo yonke i-0.01% yehla kwi-carbon content, umxholo we-manganese ophezulu uvumelekile ukuba unyuke ngo-0.06%, kodwa ubuninzi abukwazi ukudlula i-1.35%.

C Ukuncipha ngakunye kwe-0.01% kowona mxholo wekhabhoni uphezulu kuya kuvumela owona mxholo uphezulu wemanganese ukuba unyuke nge-0.06%, kodwa ubuninzi bungagqithi kwi-1.65%.

IPropati yoomatshini

| into | G.A | GR.B |

| amandla okuqina, ≥, psi [MPa] Amandla eSivuno, ≥, psi [MPa] Igeyiji 2in.okanye 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubuncinane bobude begeyiji yobude obuyi-2in. (50mm) iya kumiselwa ngale fomula ilandelayo:

e=625000(1940)A0.2/U0.9

e = ubuncinane bobude begeyiji 2in. (50mm), ipesenti isondezwe kweyona 0.5% ikufutshane;

A = Kubalwa ngokwe-diameter yangaphandle echaziweyo yetyhubhu yegama okanye ububanzi begama lesampulu ye-tensile kunye nobukhulu bayo obuchaziweyo bodonga, kwaye ijikelezwe kwindawo ekufutshane ye-cross-sectional ye-tensile yesampuli ye-0.01 in.2 (1 mm2), kwaye Ithelekiswa ne-0.75in.2 (500mm2), nokuba yeyiphi encinci.

U = ubuncinci bamandla okuqina, i-psi (MPa).

B Kwiindibaniselwano ezahlukeneyo zobukhulu obahlukeneyo besampulu zovavanyo lwe-tensile kunye namandla amiselweyo amiselweyo, ubuncinane bobude obufunekayo buboniswa kwiTheyibhile X4.1 okanye kwiTheyibhile X4.2, ngokokusebenza kwayo.

Imfuneko yoVavanyo

Uvavanyo lwe-tensile, uvavanyo lokugoba, uvavanyo lwe-hydrostatic, uvavanyo lombane olungonakalisiyo lwe-welds.

Supply Ability

Amandla okubonelela: IiToni ezingama-2000 ngeNyanga ngeBanga ngalinye le-ASTM A53/A53M-2012 iPipe yentsimbi

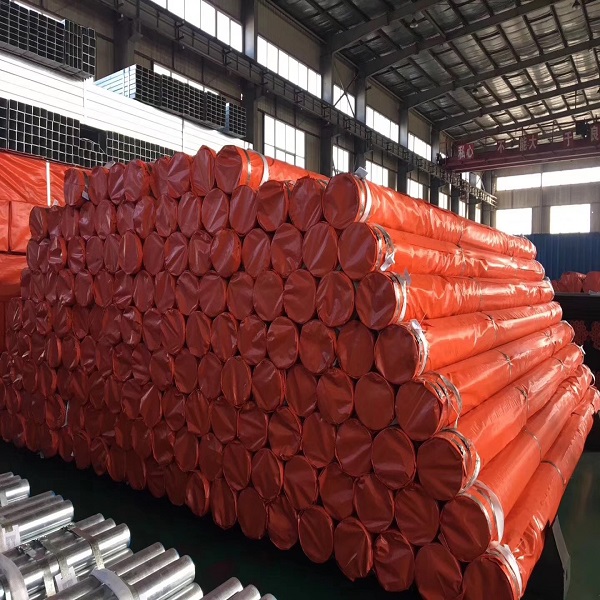

Ukupakishwa

Kwimiyanda kunye nakwiBhokisi yoMthi eyomeleleyo

Ukuhanjiswa

7-14 iintsuku ukuba isitokhwe, 30-45 iintsuku ukuvelisa

Intlawulo

30% idepsoit, 70% L/C okanye B/L ikopi okanye 100% L/C ngokubona