Umbhobho weNtsimbi oyiGalvanized

Inkampani yethu igxile kwimibhobho yentsimbi engenamthungoumbhobho owenziwe igalvanized, Umbhobho ongenamthungo oGalvanized, Umbhobho we-SMLS galvanized, I-WELDED umbhobho owenziwe ngamabati.

Uthini umahluko phakathi kwegalvaninze eshushu kunye nebandayo?

Idiphu eshushu yafaka igalvanizing kunye nokubanda kwawenza igalvanizing umahluko:

1. Galvanizing, eyaziwa ngokuba idiphu eshushu, nguye ingot inyibilike kumaqondo obushushu aphezulu, inani lezinto ezongezelelweyo endaweni, ngoko nkxu idiphu isakhiwo metal slot, icandelo metal kumaleko zinc ukutyabeka . Iingenelo zokutshisa okutshisayo kwediphu ye-galvanizing yesakhono sakhe, ukunamathela kunye nokuqina kwe-zinc coating kungcono.

"I-cold plated" okanye "i-plating", oko kukuthi isisombululo setyuwa ye-zinc nge-electrolysis, ukuya kwi-plating kwi-coating, ngokuqhelekileyo ayinalo ukufudumala, ixabiso elincinci le-zinc, indawo emanzi ilula kakhulu ukuwa.

2. Idiphu eshushu ifakwe igalvanizing (igalvanizing)

I-Hot-dip galvanizing yonyango lwekhemikhali, yi-electrochemical reaction.

I-galvanizing ebandayo yidilesi yomzimba, xuba nje i-surface layer ye-zinc, i-zinc layer ilula ukuwa. Ukwakhiwa ekusebenziseni i-galvanizing yediphu eshushu.

Inkqubo eqhubekayo yokufaka idiphu yediphu eshushu: intsimbi → ukufudumeza → ukupholisa kwiqondo lobushushu kwenziwe igalvanized → ukupholisa →

I-zinc ebandayo efakwe igalvanized yi-10-50g/m2 kuphela, eyakhe ukuxhathisa umhlwa kunediphu eshushu efakwe amagalvans umahluko omkhulu. Ifakwe igalati ngexabiso eliphantsi.

Idiphu eshushu yomzimba wentsimbi eshushu idiphu ifakwe amazimba phantsi kwemeko yokuncamathelisa kwayo yomelele, akukho lula ukuwa, nangona kukho idiphu eshushu.umbhobho owenziwe igalvanizedi-corrosion phenomenon, kodwa kwixesha elide ukuhlangabezana neemfuno zempilo, zobugcisa.

3. Umahluko kwezobuchwepheshe

Okokuqala, ngumahluko phakathi kwenkqubo: i-hot-dip galvanizing yi-workpiece degreasing, pickling, i-dipping, ukucwiliswa kolwelo kwi-zinc etyhidiweyo ixesha elithile, inokuphakanyiswa.

Ekwaziwa ngokuba electro-galvanized ebandayo galvanizing, kukusebenzisa izixhobo electrolysis umsebenzi isiqwenga ngokusebenzisa degreasing, pickling izithako post kwisisombululo zinki ityuwa, kwaye uqhagamshela izixhobo anode electrolysis; kwindawo kuzo zonke iindawo zepleyiti ye-zinc eqhagamshelwe kwisixhobo se-electrolysis esivumayo, amandla, ukusetyenziswa kwangoku ukusuka kwi-cathode ukuya kwi-anode yentshukumo ye-directional ye-workpiece iya kufakwa kumaleko we-zinc.

I-Zinc iwugqibile umahluko: akukho galvanized ebandayo eshushu-diphu efaka inkangeleko eethe-ethe eqaqambileyo, kodwa ubukhulu be-zinc yokwambathisa imiba ebandayo yokwenziwa kwegalvanizing yediphu eshushu ngamaxesha ambalwa. Ukuxhathisa umhlwa kwegalvanized kwakhona ngamaxesha amaninzi.

Isishwankathelo

Isicelo

Isetyenziswa ikakhulu kumandla kunye noxinzelelo lwamalungu, kunye nenjongo eqhelekileyo yomphunga, amanzi, igesi kunye nemibhobho yomoya.

IBanga eliPhambili

G.A, GR.B

ICandelo leMichiza

| IBanga | Icandelo %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (umbhobho ongenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (umbhobho wokuchasa odityanisiweyo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-F | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isimbuku sezi elementi zintlanu masingabi ngaphezu kwe-1.00%.

B Ngayo yonke i-0.01% yehla kwi-carbon content, umxholo we-manganese ophezulu uvumelekile ukuba unyuke ngo-0.06%, kodwa ubuninzi abukwazi ukudlula i-1.35%.

C Ukuncipha ngakunye kwe-0.01% kowona mxholo wekhabhoni uphezulu kuya kuvumela owona mxholo uphezulu wemanganese ukuba unyuke nge-0.06%, kodwa ubuninzi bungagqithi kwi-1.65%.

IPropati yoomatshini

| into | G.A | GR.B |

| amandla okuqina, ≥, psi [MPa] Amandla eSivuno, ≥, psi [MPa] Igeyiji 2in.okanye 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubuncinane bobude begeyiji yobude obuyi-2in. (50mm) iya kumiselwa ngale fomula ilandelayo:

e=625000(1940)A0.2/U0.9

e = ubuncinane bobude begeyiji 2in. (50mm), ipesenti isondezwe kweyona 0.5% ikufutshane;

A = Kubalwa ngokwe-diameter yangaphandle echaziweyo yetyhubhu yegama okanye ububanzi begama lesampulu ye-tensile kunye nobukhulu bayo obuchaziweyo bodonga, kwaye ijikelezwe kwindawo ekufutshane ye-cross-sectional ye-tensile yesampuli ye-0.01 in.2 (1 mm2), kwaye Ithelekiswa ne-0.75in.2 (500mm2), nokuba yeyiphi encinci.

U = ubuncinci bamandla okuqina, i-psi (MPa).

B Kwiindibaniselwano ezahlukeneyo zobukhulu obahlukeneyo besampulu zovavanyo lwe-tensile kunye namandla amiselweyo amiselweyo, ubuncinane bobude obufunekayo buboniswa kwiTheyibhile X4.1 okanye kwiTheyibhile X4.2, ngokokusebenza kwayo.

Imfuneko yoVavanyo

Uvavanyo lwe-tensile, uvavanyo lokugoba, uvavanyo lwe-hydrostatic, uvavanyo lombane olungonakalisiyo lwe-welds.

Supply Ability

Amandla okubonelela: IiToni ezingama-2000 ngeNyanga ngeBanga ngalinye le-ASTM A53/A53M-2012 iPipe yentsimbi

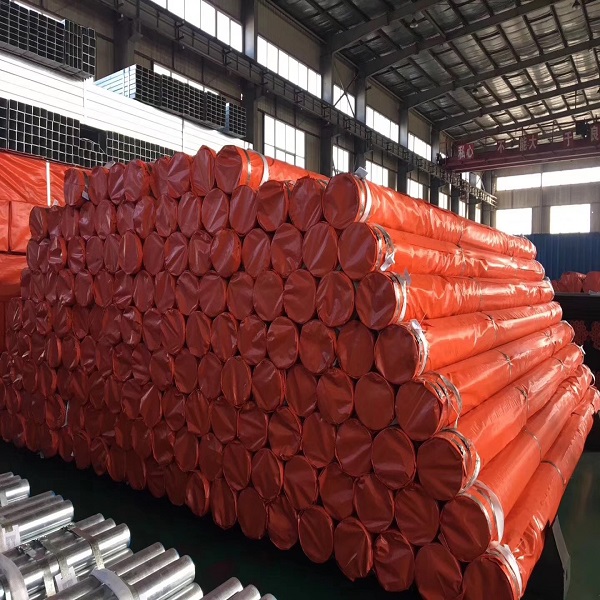

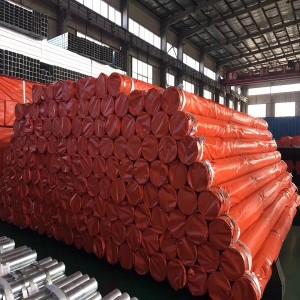

Ukupakishwa

Kwimiyanda kunye nakwiBhokisi yoMthi eyomeleleyo

Ukuhanjiswa

7-14 iintsuku ukuba isitokhwe, 30-45 iintsuku ukuvelisa

Intlawulo

30% idepsoit, 70% L/C okanye B/L ikopi okanye 100% L/C ngokubona