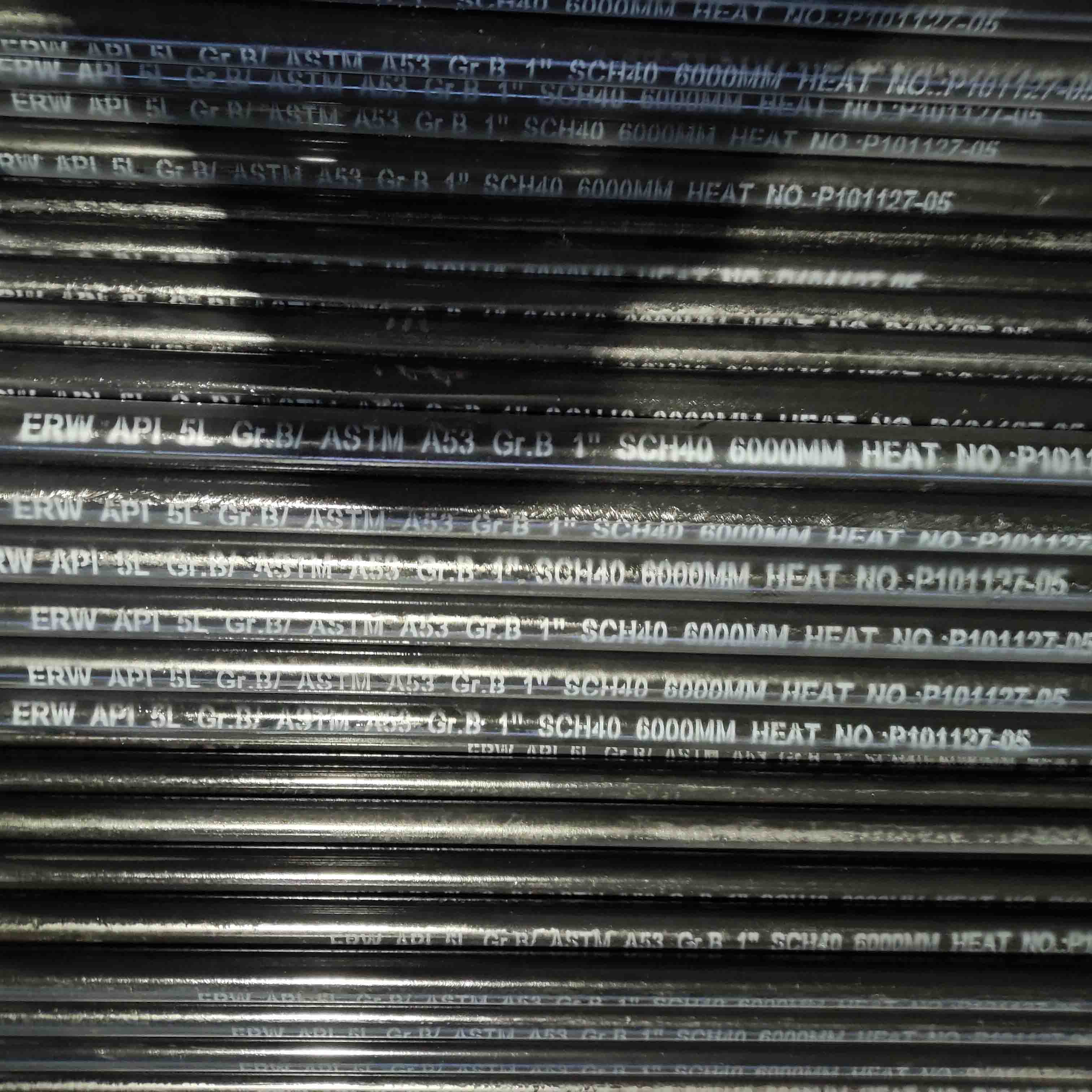

[Copy] ASME SA-106/SA-106M-2015 Carbon steel pipe

| Standard: ASTM SA106 | Alloy Or Not: Not |

| Grade Group: GR.A,GR.B,GR.C etc | Application: Fluid Pipe |

| Thickness: 1 - 100 mm | Surface Treatment: As customer's requirement |

| Outer Diameter(Round): 10 - 1000 mm | Technique: Hot Rolled |

| Length: Fixed length or random length | Heat treatment: Annealing/normalizing |

| Section Shape: Round | Special Pipe: High temperature |

| Place of Origin: China | Usage: Construction, Fluid Transportation |

| Certification: ISO9001:2008 | Test: ECT/CNV/NDT |

Seamless steel pipe for high temperature operation ASTM A106, suitable for high temperature

Grade of high-quality carbon structural steel: GR.A,GR.B,GR.C

| Composition, % | |||

| Grade A | Grade B | Grade C | |

| Carbon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.035 | 0.035 | 0.035 |

| Silicon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Copper, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.35%. | |||

| B Unless otherwise specified by the purchaser, for each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.65%. | |||

| C These five elements combined shall not exceed 1%. | |||

| Grade A | Grade B | Grade C | ||||||

| Tensile strength, min, psi(MPa) | 48 000(330) | 60 000(415) | 70 000(485) | |||||

| Yield strength, min, psi(MPa) | 30 000(205) | 35 000(240) | 40 000(275) | |||||

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | |||

| Elongation in 2 in. (50 mm), min, % Basic minimum elongation transverse strip tests, and for all small sizes tested in full section |

35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| When standard round 2-in. (50-mm) gauge length test specimen is used | 28 | 20 | 22 | 12 | 20 | 12 | ||

| For longitudinal strip tests | A | A | A | |||||

| For transverse strip tests, a deduction for each 1/32-in. (0.8-mm) decrease in wall thickness below 5/16 in. (7.9 mm) from the basic minimum elongation of the following percentage shall be made | 1.25 | 1.00 | 1.00 | |||||

| A The minimum elongation in 2 in. (50 mm) shall be determined by the following equation: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| for inch-pound units, and | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| for SI units, | ||||||||

| where: e = minimum elongation in 2 in. (50 mm), %, rounded to the nearest 0.5%, A = cross-sectional area of the tension test specimen, in.2 (mm2), based upon specified outside diameter or nominal specified outside diameter or nominal specimen width and specified wall thickness, rounded to the nearest 0.01 in.2 (1 mm2). (If the area thus calculated is equal to or greater than 0.75 in.2 (500 mm2), then the value 0.75 in.2 (500 mm2) shall be used.), and U = specified tensile strength, psi (MPa). |

||||||||

In addition to ensuring chemical composition and mechanical properties, hydrostatic tests are performed one by one, and flaring and flattening tests are performed. . In addition, there are certain requirements for the microstructure, grain size, and decarburization layer of the finished steel pipe.

Supply Ability: 1000 Tons Per Month Per Grade of ASTM SA-106 Steel Pipe

In Bundles And In Strong Wooden Box

7-14 days if in stock, 30-45 days to produce

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight

Write your message here and send it to us

![[Copy] ASME SA-106/SA-106M-2015 Carbon steel pipe Featured Image](https://ecdn6.globalso.com/upload/p/800/image_product/2024-04/660a5654e5e9618799.png)

![[Copy] ASME SA-106/SA-106M-2015 Carbon steel pipe](https://ecdn6.globalso.com/upload/p/800/source/2024-04/660b6661de0b547663.png)

![[Copy] ASME SA-106/SA-106M-2015 Carbon steel pipe](https://ecdn6.globalso.com/upload/p/800/source/2024-04/660b66e9716b973035.jpg)

![[Copy] ASME SA-106/SA-106M-2015 Carbon steel pipe](https://ecdn6.globalso.com/upload/p/800/source/2024-04/660b66eb0049671067.jpg)