Hot finished structural hollow sections of non-alloy and fine grain steels

| Standard: BSEN10210-1-2006 | Alloy Or Not: Not |

| Grade Group: S235GRH, S275JOH, S275J2H, S355JOH, S355J2H | Application: Structure |

| Thickness: 1 - 100 mm | Surface Treatment: As customer's requirement |

| Outer Diameter(Round): 10 - 1000 mm | Technique: Hot Rolled or Cold Rolled |

| Length: Fixed length or random length | Heat treatment: Annealing/Normalizing/Stress Relieving |

| Section Shape: Round | Special Pipe: Thick Wall Pipe |

| Place of Origin: China | Usage: Mechanical structure, general structure |

| Certification: ISO9001:2008 | Test: ECT/UT |

It Is Mainly Used for Mechanical structure,general structure.

S235GRH, S275JOH, S275J2H, S355JOH, S355J2H

|

grade |

Deoxygenated Type a |

% Mass, maximum |

|||||||

|

Steel name |

Steel nmber |

C Prescribed wall thickness mm |

Si |

Mn |

P |

S |

Nbc |

||

|

≤ 40 |

> 40≤ 120 |

||||||||

|

S235JRH |

1.0039 |

FN |

0.17 |

0.20 |

— |

1.40 |

0.040 |

0.040 |

0.009 |

|

S275J0H |

1.0149 |

FN |

0.20 |

0.22 |

— |

1.50 |

0.035 |

0.035 |

0.009 |

|

S275J2H |

1.0138 |

FF |

0.20 |

0.22 |

— |

1.50 |

0.030 |

0.030 |

— |

|

S355J0H |

1.0547 |

FN |

0.22 |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

0.009 |

|

S355J2H |

1.0576 |

FF |

0.22 |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

— |

|

S355K2H |

1.0512 |

FF |

0.22 |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

— |

|

a The definition of deoxidation method is as follows: FN = Boiling steel is not allowed FF = fully-killed steel containing nitrogen-binding elements in an amount sufficient to bind possible nitrogen (E.g. 0.020% minimum total aluminum or 0.015% soluble aluminum) b It is allowed to exceed the specified value, as long as the N content increases by 0.001%, the maximum content of P decreases by 0.005% at the same time. The N content in the smelting analysis should not exceed 0.012%. c If the chemical composition shows a minimum total aluminum content of 0.020% and a minimum Al / N ratio of 2: 1, or if other sufficient nitrogen-binding elements are present, the above maximum nitrogen content limits do not apply. Nitrogen binding elements shall be noted in the inspection documents.

|

|||||||||

| Grade | Minimum yield | tensile strength | Minimum elongation | Minimum impact power | |||||||||||||

| Steel name | Steel number | Standard thickness | Standard thickness | Standard thickness | Standard thickness | ||||||||||||

| ≤16 | > 16 | > 40 | > 63 | > 80 | > 100 | ≤3 | > 3 | > 100 | ≤40 | >40≤63 | >63≤100 | >100≤120 | -20℃ | 0℃ | 20℃ | ||

| ≤ 40 | ≤ 63 | ≤ 80 | ≤ 100 | ≤ 120 | ≤100 | ≤ 120 | |||||||||||

| S235JRH | 1.0039 | 235 | 225 | 215 | 215 | 215 | 195 | 360-510 | 360-510 | 360-500 | 26 | 25 | 24 | 22 | - | - | 27 |

| S275J0Hc | 1.0149 | 275 | 265 | 255 | 245 | 235 | 225 | 430-580 | 410-560 | 400-540 | 23 | 22 | 21 | 19 | - | 27 | - |

| S275J2H | 1.0138 | 27 | - | - | |||||||||||||

| S355J0Hc | 1.0547 | 355 | 345 | 355 | 325 | 315 | 295 | 510-680 | 470-630 | 450-600 | 22 | 21 | 20 | 18 | - | 27 | - |

| S355J2H | 1.0576 | 27 | - | - | |||||||||||||

| S355K2H | 1.0512 | 40 | - | - | |||||||||||||

| a Longitudinal sample value. The standard value of the transverse specimen is 2% lower than this value.b For thicknesses <3mm, see 9.2.2.c Only when option 1.3 is applied, confirmation of impact performance is required.d See 6.6.2 for the impact properties of small-sized specimens.e This value is equivalent to 27J at -30 ° C (see EN 1993-1-1). | |||||||||||||||||

Hardness Test, Tension Tests, Nondestructive Tests, Steel Cleanliness, Hardenability, Flaring Test

Supply Ability: 2000 Tons Per Month Per Grade Of BSEN10210-1-2006 Steel Pipe

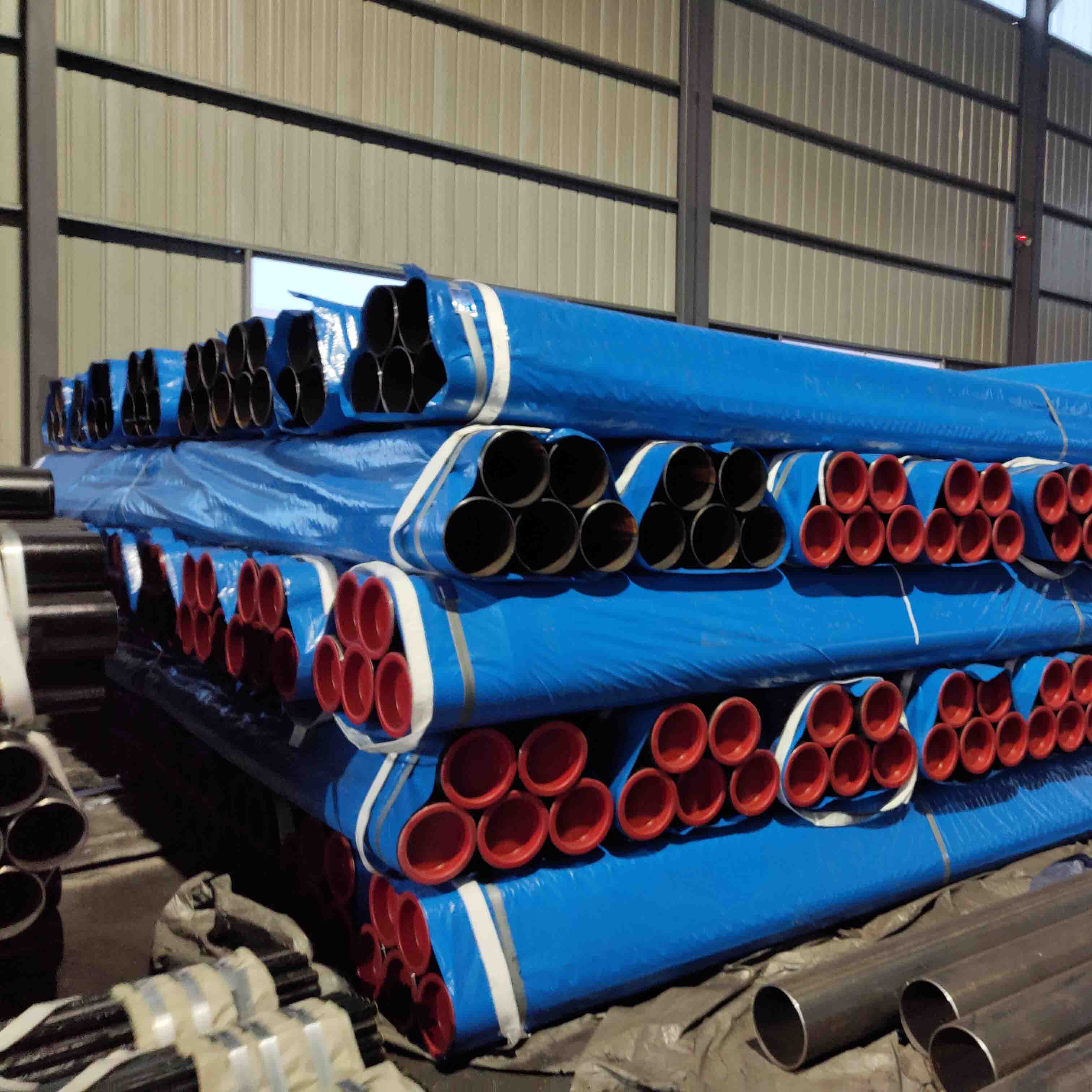

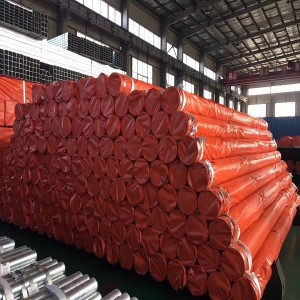

In Bundles And In Strong Wooden Box

7-14 days if in stock, 30-45 days to produce

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight