Manufacturer of For High Pressure And Temperature Thick Wall Alloy Seamless Steel Pipe

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Manufacturer of For High Pressure And Temperature Thick Wall Alloy Seamless Steel Pipe, To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Alloy Seamless Steel Pipe, High Pressure And Temperature Thick Wall Alloy Seamless Steel Pipe, Thick Wall Alloy Seamless Steel Pipe, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. “Your satisfaction is our happiness”.

Overview

Application

Seamless steel pipe for high pressure fertilizer equipment is a high quality carbon structural steel and alloy steel seamless steel pipe suitable for chemical equipment and pipeline.

Main Grade

Grade of high-quality carbon structural steel: 10#、20#

Chemical Component

| Chemical Component/% | ||||||||||||

| NO | C | Si | Mn | Cr | Mo | V | W | Nb | Ni | P S | ||

| no more than | ||||||||||||

| 10 | 0. 07-0. 13 | 0. 17 -0. 37 | 0.35 -0. 65 | - | - | - | - | - | - | 0.025 | 0.015 | |

| 20 | 0. 17 -0. 23 | 0.17 -0. 37 | 0. 35-0.65 | - | - | - | - | - | - | 0.025 | 0.015 | |

| Q345Ba | 0. 12 -0. 20 | 0.20-0. 50 | 1.20-1.70 | <0. 30 | <0. 10 | mis | - | <0.07 | W0. 50 | 0.025 | 0.015 | |

| Q345C” | 0. 12 -0. 20 | 0.20 -0. 50 | 1.20 -1. 70 | W0. 30 | <0. 10 | <0. 15 | - | W0.07 | <0. 50 | 0.025 | 0.015 | |

| Q345D” | 0. 12 -0. 18 | 0.20 -0. 50 | 1. 20~1.70 | W0. 30 | <0. 10 | <0. 15 | - | W0.07 | <0. 50 | 0. 025 | 0.015 | |

| Q345Ea*b | 0. 12 -0. 18 | 0. 20-0. 50 | 1. 20 -1.70 | W0. 30 | <0. 10 | <0. 15 | - | <0.07 | <0. 50 | 0. 025 | 0.01 | |

| 12CrMo | 0. 08-0. 15 | 0.17 -0. 37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40-0. 55 | - | - | - | - | 0. 025 | 0.015 | |

| 15CrMo | 0. 12 -0. 18 | 0. 17 -0. 37 | 0. 40-0. 70 | 0. 80-1. 10 | 0. 40-0.55 | - | - | - | - | 0. 025 | 0. 015 | |

| 12Cr2Mo | 0. 08-0. 15 | <0. 50 | 0. 40-0.6 | 2.00-2. 50 | 0. 90-1. 13 | - | - | - | - | 0.025 | 0. 015 | |

| 12Cr5Mo | <0. 15 | <0.50 | <0. 60 | 4. 00-6.00 | 0. 40-0. 60 | - | - | - | <0. 60 | 0. 025 | 0. 015 | |

| lOMoWVNb | 0. 07-0. 13 | 0. 50-0.8 | 0. 50-0.8 | - | 0. 60-0. 90 | 0. 30-0. 50 | 0. 50-0. 90 | 0. 06-0. 12 | - | 0.025 | 0.015 | |

| 12SiMoVNb | 0.08 -0. 14 | 0.50 -0.8 | 0. 60-0. 90 | - | 0. 90-1. 10 | 0. 30-0. 50 | - | 0. 04-0.08 | - | 0.025 | 0.015 | |

| awhen it is necessary to add fine grain elements, the steel shall contain at least one of Al, Nb, V and Ti. The added fine grain elements shall be indicated in the quality certificate. Ti content shall not be more than 0.20% | ||||||||||||

| bAl content in steel shall not be less than 0.020%, or ala content in steel shall not be less than 0.015% | ||||||||||||

Mechanical Property

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Test Requirement

In addition to ensuring the chemical composition and mechanical properties, the steel pipe directly rolled by ingot shall be subject to low power inspection, and eddy current inspection or magnetic flux leakage inspection can be used instead of hydraulic test.

Supply Ability

2000 Tons Per Month Per Grade of Seamless steel tubes for high-pressure

chemical fertilizer processing equipments.

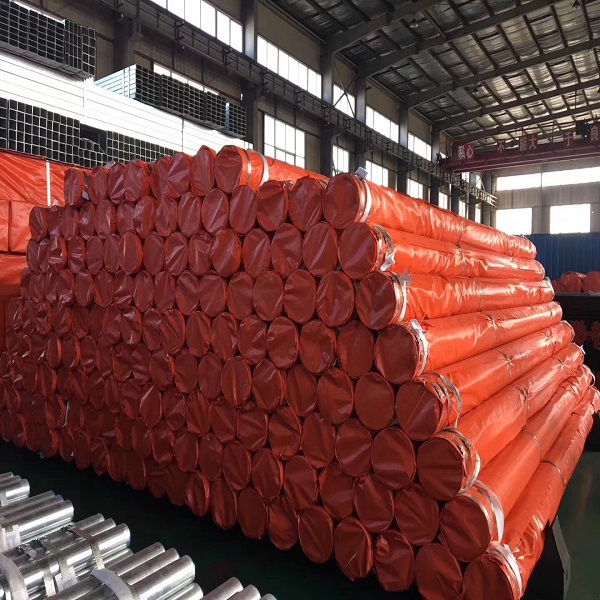

Packaging

In Bundles And In Strong Wooden Box

Delivery

7-14 days if in stock, 30-45 days to produce

Payment

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight