1. Introduction to seamless steel pipe

Seamless steel pipe is a steel pipe with a hollow cross-section and no seams around it. It has high strength, corrosion resistance and good thermal conductivity. Due to its excellent performance, seamless steel pipes are widely used in various fields such as petroleum, chemical industry, electric power, and construction.

2. Seamless steel pipe production process

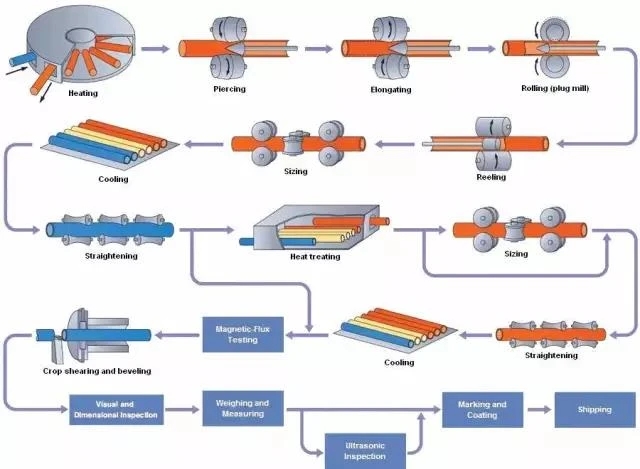

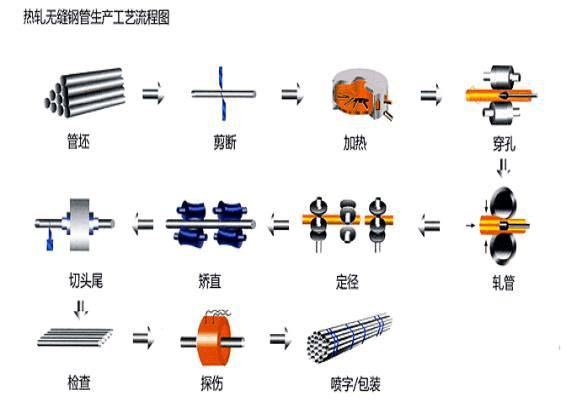

The production process of seamless steel pipe mainly includes the following steps:

a. Prepare raw materials: Select appropriate steel billets, which require smooth surface, no bubbles, no cracks, and no obvious defects.

b. Heating: Heating the steel billet to a high temperature to make it plastic and easy to form.

c. Perforation: The heated steel billet is perforated into a tube blank through a perforation machine, that is, a preliminary formed steel pipe.

d. Pipe rolling: The tube blank is rolled multiple times to reduce its diameter, increase its wall thickness, and eliminate internal stress.

e. Sizing: The steel pipe is finally shaped through a sizing machine so that the diameter and wall thickness of the steel pipe meet the standard requirements.

f. Cooling: The shaped steel pipe is cooled to increase its hardness and strength.

g. Straightening: Straighten the cooled steel pipe to eliminate its bending deformation.

h. Quality inspection: Conduct quality inspection on finished steel pipes, including inspection of size, wall thickness, hardness, surface quality, etc.

3. The manufacturing process of seamless steel pipe#Seamless Steel Pipe#

3. The manufacturing process of seamless steel pipe#Seamless Steel Pipe#

The specific process of manufacturing seamless steel pipes is as follows:

a. Prepare raw materials: Select appropriate steel billets, which require no defects, no bubbles, and no cracks on the surface.

b. Heating: Heating the steel billet to a high temperature state, the general heating temperature is 1000-1200℃.

c. Perforation: The heated steel billet is perforated into a tube blank through a piercing machine. At this time, the tube blank has not yet been completely formed.

d. Pipe rolling: The tube blank is sent to the pipe rolling machine for multiple rollings to reduce the diameter of the tube and increase the wall thickness, while eliminating internal stress.

e. Reheating: Reheat the rolled tube blank to eliminate its internal residual stress.

f. Sizing: The steel pipe is finally shaped through a sizing machine so that the diameter and wall thickness of the steel pipe meet the standard requirements.

g. Cooling: Cool the shaped steel pipe, generally using water cooling or air cooling.

h. Straightening: Straighten the cooled steel pipe to eliminate its bending deformation.

i. Quality inspection: Conduct quality inspection on finished steel pipes, including inspection of size, wall thickness, hardness, surface quality, etc.

During the manufacturing process, the following points need to be noted: first, the quality and stability of the raw materials must be ensured; second, the temperature and pressure must be strictly controlled during the piercing and rolling processes to avoid cracks and deformation; finally, sizing and cooling The stability and straightness of the steel pipe must be maintained during the process.

4. Quality control of seamless steel pipes

In order to ensure the quality of seamless steel pipes, the following aspects need to be controlled:

a. Raw materials: Use high-quality steel billets to ensure that there are no defects, bubbles, or cracks on the surface. At the same time, it is necessary to ensure that the chemical composition and mechanical properties of raw materials meet standard requirements.

b. Production process: Strictly control each process in the production process to ensure that the quality of each process is stable and reliable. Especially during the piercing and rolling processes, temperature and pressure must be strictly controlled to avoid cracks and deformation.

c. Dimensions: Conduct dimensional inspection on finished steel pipes to ensure that their diameter and wall thickness meet standard requirements. Special measuring instruments can be used for measurement, such as micrometers, wall thickness measuring instruments, etc.

d. Surface quality: Conduct surface quality inspection on finished steel pipes, including surface roughness, presence of cracks, folding and other defects. Detection can be done using visual inspection or specialized testing instruments.

e. Metallographic structure: Conduct metallographic structure testing on the finished steel pipe to ensure that its metallographic structure meets the standard requirements. Generally, a microscope is used to observe the metallographic structure and check whether there are microscopic defects.

f. Mechanical properties: Mechanical properties of finished steel pipes are tested, including hardness, tensile strength, yield strength and other indicators. Tensile testing machines and other equipment can be used for testing.

Through the above quality control measures, the quality of seamless steel pipes can be ensured to be stable and reliable, meeting the needs of various application fields.

5. Application areas of seamless steel pipes

Seamless steel pipes have a wide range of applications, mainly including the following aspects:

a. Petroleum industry: used in oil well pipes, oil pipelines and chemical pipelines in the petroleum industry. Seamless steel pipes have the characteristics of high strength, corrosion resistance, and high temperature resistance, and can ensure the safe and stable operation of the petroleum industry.

b. Chemical industry: In the chemical industry, seamless steel pipes are widely used in various chemical reaction pipelines, fluid transportation pipelines, etc. Due to its strong corrosion resistance, it can resist the erosion of various chemical substances, ensuring the production safety and efficiency of the chemical industry.

Seamless steel pipe is a round steel with a hollow section and no seams around it. It has the characteristics of high strength, corrosion resistance, high temperature and low temperature resistance. According to different manufacturing processes, seamless steel pipes can be divided into two types: hot-rolled pipes and cold-rolled pipes. Hot-rolled pipes are made by heating steel billets at high temperatures for perforation, rolling, cooling and other processes, and are suitable for large and complex cross-section steel pipes; cold-rolled pipes are made by cold rolling at room temperature and are suitable for production Smaller cross-section and higher precision steel pipes.

Post time: Nov-28-2023