Seamless steel pipe is perforated by the whole round steel, and the steel pipe with no weld on the surface is called seamless steel pipe. According to the production method, the seamless steel pipe can be divided into hot-rolled seamless steel pipe, cold-rolled seamless steel pipe, cold-drawn seamless steel pipe, extruded seamless steel pipe, pipe jacking and so on. According to the section shape, the seamless steel pipe is divided into two kinds: round and shaped. The maximum diameter is 900mm and the minimum diameter is 4mm. According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes. Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

According to the use is divided into general purpose (for water, gas pipelines and structural parts, mechanical parts) and special (for boilers, geological exploration, bearings, acid resistance, etc.) two categories.

The general purpose seamless steel pipe is rolled by ordinary carbon structural steel, low alloy structural steel or alloy structural steel, and has the largest output, mainly used as a pipeline or structural part for conveying fluids. There are many kinds of seamless pipes for special purposes, such as boiler seamless pipes, chemical power pipes, geological seamless pipes and petroleum seamless pipes. The seamless steel pipe has a hollow cross-section and is widely used as a pipeline for conveying fluids, such as pipelines for conveying oil, natural gas, gas, water and some solid materials.

Seamless steel pipe production process:

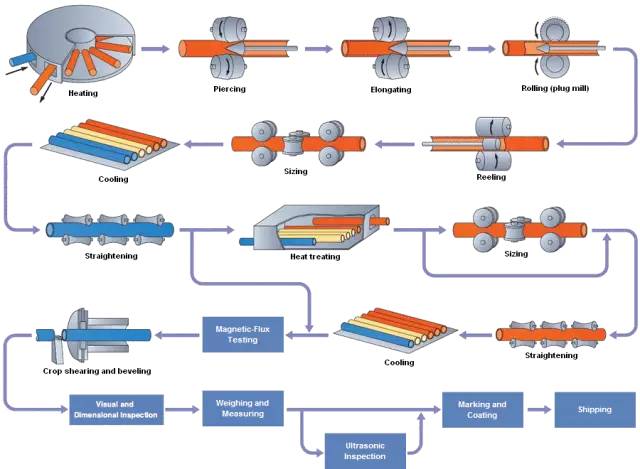

① Main production process of hot-rolled seamless steel pipe (△ Main inspection process) :

Preparation and inspection △→ Heating → perforating → Rolling → reheating → Sizing → Heat treatment △→ Straightening → Finishing → Inspection △ (non-destructive, physical and chemical, table inspection) → storage

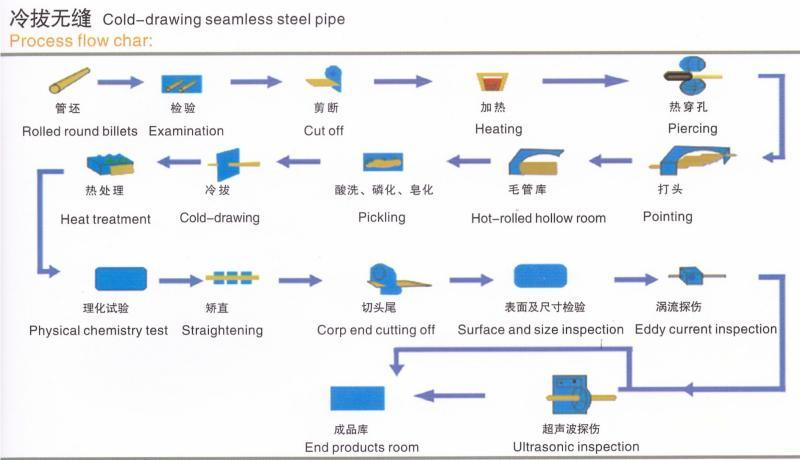

② Cold rolled (drawn) seamless steel pipe main production process:

Blank preparation → pickling lubrication → Cold rolling (drawing) → Heat treatment → straightening → finishing → inspection

General seamless steel pipe production process can be divided into two kinds of cold drawing and hot rolling, cold rolled seamless steel pipe production process is generally more complex than hot rolling, the tube billet first to carry out three roller continuous rolling, extrusion after sizing test, if the surface does not respond to the crack after the round tube to be cut by the cutting machine, cutting the growth of about one meter blank. Then enter the annealing process, annealing with acidic liquid pickling, pickling should pay attention to whether there is a large number of bubbles on the surface, if there is a large number of bubbles, indicating that the quality of the steel pipe can not meet the corresponding standards. The appearance of cold-rolled seamless steel pipe is shorter than that of hot-rolled seamless steel pipe, the wall thickness of cold-rolled seamless steel pipe is generally smaller than that of hot-rolled seamless steel pipe, but the surface looks brighter than that of thick-walled seamless steel pipe, the surface is not too rough, and the caliber is not too much burr.

The delivery state of hot-rolled seamless steel pipe is generally delivered after hot rolled heat treatment. Hot rolled seamless steel pipe after the quality inspection to go through the staff's strict manual selection, after the quality inspection to carry out the surface oil, and then followed by a number of cold drawing experiment, hot rolling treatment to carry out the test of perforation, if the perforation enlargement is too large to be straightener. After straightening, it is sent to the flaw detection machine by the transmission device for flaw detection experiment, and finally labeled, formatted and placed in the warehouse.

Round tube blank → heating → perforation → three-roll skew rolling, continuous rolling or extrusion → Stripping → sizing (or reducing) → Cooling → straightening → water pressure test (or inspection) → Marking → Seamless steel pipe in storage is made of steel ingot or solid tube blank through perforation to make capillary tube, and then hot rolling, cold rolling or cold drawing. The specifications of the seamless steel pipe are expressed by the outer diameter * the wall thickness of millimeters.

The outer diameter of the hot-rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-200mm, the outer diameter of the cold-rolled seamless steel pipe can be 6mm, the wall thickness can be 0.25mm, the outer diameter of the thin-walled pipe can be 5mm, the wall thickness is less than 0.25mm, and the size accuracy is higher than that of the hot-rolled seamless pipe.

Post time: Aug-28-2023