Shiinaha Kuleyl Dufan ee Beebka Birta ah/Birta Alxanka leh, ASTM A53 API 5L

Dulmar

Waxay noqon kartaa xisaabtankayada si aan u qancinno dookyadaada oo aan si karti leh ku siinno. Ku qanacsanaantaadu waa abaalmarintayada ugu weyn. Waxaan horay u raadineynaa booqashadaada si aan u kobcin wadajirka ah. Dadaalkayaga dartii, alaabtayadu waxay kasbadeen kalsoonida iibsadayaasha waxayna ahaayeen kuwo si siman loo iibsan karo gudaha iyo dibaddaba. Warshadeenu waxay ku adkaysanaysaa mabda'a "Tayada Koowaad, Horumar Waara", waxayna qaadataa "Ganacsiga Daacadda ah, Faa'iidooyinka Labada Dhinac" sida yoolkayaga la horumarin karo. Dhammaan xubnaha waxay si daacad ah ugu mahadcelinayaan dhammaan taageerada macaamiisha hore iyo kuwa cusub. Waxaan sii wadi doonaa inaan si adag u shaqeyno waxaanan ku siin doonaa alaabooyinka iyo adeegga ugu tayada sarreeya.

Ku saabsan birta kaarboonka ee alxanka leh iyo tuubada aan xuduudka lahayn, si loo kordhiyo awoodda iska caabbinta daxalka, waxaa jiri doona nooc ka mid ah daaweynta dusha sare ee tuubada. Mid ka mid ah inta badan la isticmaalo waa koodhka zinc (galvanize). Waxaa jira laba hab oo galvanize ah: glavanizing qabow (electrogalvanizing) iyo galvanizing kulul. Sababtoo ah dhibaatada deegaanka, glavanizing qabow ayaa xaddiday Shiinaha, galvanizing kulul sidoo kale looma isticmaali karo sida tuubada biyaha, laakiin waxaa si ballaaran loo isticmaalaa dab-damiska, korontada iyo waddooyinka.

Galvanizing qabow waa electrogalvanizing, sababtoo ah xadka farsamada, jaakad zinc ma badna, badiyaa 10-50g / m2, sidaas darteed, awooddeeda caabbinta daxalka ayaa ka yar galvanizing kulul. Wasaaradda dhismuhu waxay si rasmi ah u soo afjartay dabar-goynta tuubooyinka qaboojiya ee leh tignoolajiyada dib u dhaca, waxaana mamnuuc ah in loo isticmaalo tuubooyinka galvanized ee qabow ee biyaha iyo gaaska. Lakabka galvanized ee tuubada birta galvanized qabow waa lakabka korantada, iyo lakabka zinc iyo substrate tuubada birta ayaa si madaxbanaan loo dahaadhay. Lakabka zinc waa mid khafiif ah, lakabka zinc wuxuu si fudud ugu dheggan yahay substrate-ka tuubada birta oo ay fududahay inuu dhaco. Sidaa darteed, iska caabbinta daxalka ayaa liidata.

Lakabka dahaadhka tuubbada kulul waxa samaysma falcelinta birta dhalaalaysa iyo substrate-ka birta, si ay substrate-ka iyo lakabka dahaadhku isu geeyaan, lakabka dahaadhkuna ma fududa in uu dhaco. Galvanizing Qulqulka kulul wuxuu leeyahay faa'iidooyinka dahaarka labbiska ah, dhejinta xooggan iyo nolosha adeegga dheer. Substrate-ka tuubada birta ah ee kulul-muquufinta iyo xalinta dhalaalka dhalaalaysa waxay maraan falcelin jidheed iyo kiimiko oo adag si ay u sameeyaan lakabka daxalka zinc-birta u adkaysta oo leh qaab dhismeed is haysta. Lakabka daawaha waxaa lagu dhex daraa lakabka zinc saafiga ah iyo substrate-ka tuubada birta, sidaa darteed iska caabbinta daxalka waa mid xoogan.

Codsiga

Waxaa inta badan loo isticmaalaa qaybaha xoogga iyo cadaadiska, iyo ujeedada guud uumiga, biyaha, gaaska iyo tuubooyinka hawada.

Fasalka ugu weyn

GR.A, GR.B

Qayb Kiimiko ah

| Darajo | Qayb%,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Nooca S (tuubo aan toos ahayn) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca E (tuubo alxanka iska caabin ah) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca F (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Wadarta shantan curiye waa in aanay ka badnaan 1.00%.

B 0.01% kasta oo hoos u dhaca kaarboonka ugu badan, waxa ku jira manganese ugu badnaan waxa loo ogolyahay in uu kordho 0.06%, laakiin ugu badnaan kama badnaan karo 1.35%.

C 0.01% kasta oo hoos u dhaca kaarboonka ugu badan wuxuu u oggolaanayaa ugu badnaan maadada manganese inay korodho 0.06%, laakiin ugu badnaan waa inaanu ka badnayn 1.65%.

Hantida Makaanikada

| shayga | GR.A | GR.B |

| xoogga xajinta, ≥, psi [MPa] Xoogga Wax-soo-saarka, ≥, psi [MPa] Qiyaas 2in.ama 50mm elongation | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Kordhinta ugu yar ee dhererka cabbirka 2in. (50mm) waa in lagu go'aamiyaa qaacidooyinka soo socda:

e=625000(1940)A0.2/U0.9

e = dhererka ugu yar ee cabbirka 2in. (50mm), boqolkiiba waxa lagu soo koobay 0.5% ee ugu dhow;

A = Waxaa la xisaabiyaa iyadoo loo eegayo dhexroorka bannaanka ee la cayimay ee tuubada magaca ama ballaca magaca ee muunadda xajinta iyo dhumucdeeda darbi ee la cayimay, oo lagu soo koobay qaybta ugu dhow ee muunadda xajinta ee 0.01 in.2 (1 mm2), waxaana la barbar dhigayaa 0.75in.2 (500mm2), hadba kii ka yar.

U = la cayimay xoogga xajinta ugu yar, psi (MPa).

B Isku-darka kala duwan ee cabbirrada kala duwan ee shaybaarrada tijaabada xajinta iyo xoogga ugu yar ee la qoray, dhererka ugu yar ee loo baahan yahay ayaa lagu muujiyey Shaxda X4.1 ama Shaxda X4.2, iyadoo loo eegayo ku habboonaanteeda.

Shuruudaha Imtixaanka

Tijaabada xamaasadda, tijaabada foorarsiga, tijaabada hydrostatic, tijaabada korantada ee alxanka oo aan burbursanayn.

Awood-siinta

Awooda Sahayda: 2000 Ton bishiiba Fasalka ASTM A53/A53M-2012 Dhuumaha Bir

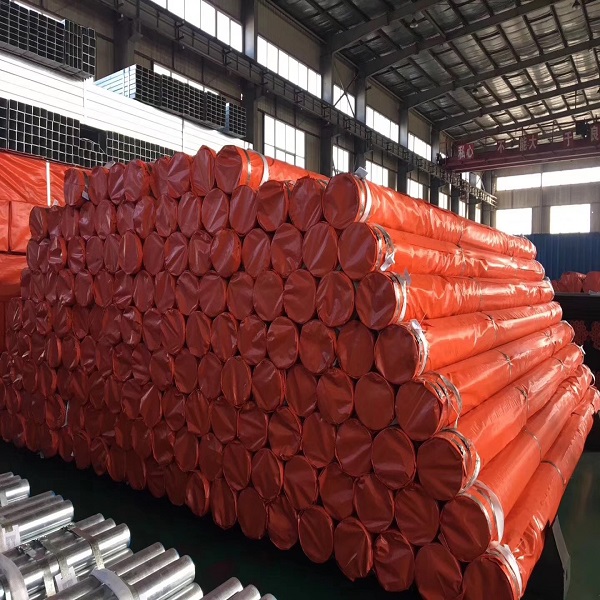

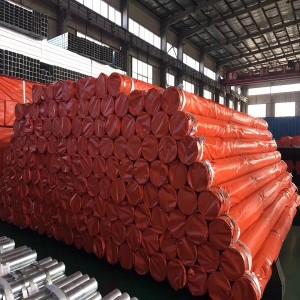

Baakadaha

Xirmooyinka iyo Sanduuqa Alwaaxda ee Xoogan

gaarsiin

7-14 maalmood haddii kaydka, 30-45 maalmood si loo soo saaro

Lacag bixinta

30% deebaaji, 70% L/C ama nuqul B/L ama 100% L/C marka la eego