Dhuumaha Biraha Galvanized

Shirkadeena waxay ku takhasustay dhoofinta dhuumaha birta ah ee aan xidhnayntuubo galvanized, Dhuumaha Galvanized oo aan Xumaan lahayn, Dhuumaha galvanized SMLS, Dhuumaha galvanized welded.

Waa maxay farqiga u dhexeeya galvaninzed kulul iyo qabow galvanized?

Galvanizing-kulul iyo galvanization qabow ayaa keenay farqiga:

1. Galvanizing, sidoo kale loo yaqaan galvanized maquufin kulul, Isagu waa ingot dhalaalay heerkulka sare, tiro ka mid ah walxaha dheeriga ah ee meel, ka dibna la rusheeyey booska qaab dhismeedka biraha galvanized, qaybta birta on lakabka ah ee daahan zinc . Faa'iidooyinka daxalka galvanizing kulul ee kuleyl ah ee awoodiisa, adhesion iyo engegnaanta ee daahan zinc ayaa ka wanaagsan

"Cold plated" ama "dalajin", tusaale ahaan xalalka milixda zinc by electrolysis, si dahaarka on daahan, guud ahaan ma haysan kuleyl, xaddi yar oo zinc ah, deegaanka qoyan waa mid aad u fudud in ay dhacaan.

2. Galvanized-kulul kulul (galvanized)

Galvanizing-ku-kulul waa daawaynta kiimikaad, waa falcelinta korantada.

Galvanizing qabow waa ciwaanka jireed, kaliya caday lakabka dushiisa ee zinc, lakabka zinc waa sahlan tahay inuu dhaco. Dhisidda isticmaalka galvanization-ka kulul ee kulul.

Geedi socodka galvanization-ka kulul ee joogtada ah: birta → kululaynta → qaboojinta heerkulka galvanized galvanized → qaboojinta →

Zinc galvanized qabow waa kaliya 10-50g/m2, iska caabin daxalka u gaar ah marka loo eego maquufin kulul galvanized badan oo kala duwan. Galvanized by qiimo jaban.

Jirka birta la galvanized ee kulul waa mid kulul oogada galvanized hoosteeda xaalada ay ku dheggan tahay oo xoogan, ma fududa in la dhaco, inkastoo ay jiraan maro kulultuubo galvanizedifafaale daxalka, laakiin muddo aad u dheer si loo buuxiyo farsamada, shuruudaha caafimaadka.

3. Farqiga u dhexeeya farsamada

First of dhan, waa farqiga u dhexeeya geedi socodka: galvanizing kulul-muquufin waa workpiece degreasing, pickling, quusin, qalajinta immersion dareere ee zinc la dhalaaliyay muddo cayiman, waa la kici karaa.

Sidoo kale loo yaqaan galvanizing qabow electro-galvanized, waa in la isticmaalo qalabka korantada shaqada gabal shaqo iyada oo hoos u dhigista, pickling maaddooyinka post galay xalka milixda zinc, iyo xidhi qalabka electrolysis anode; meel guud ahaan qaybo ka mid ah saxan zinc ku xiran qalabka electrolysis togan, koronto, isticmaalka hadda ka cathode in anode ee dhaqdhaqaaqa jihada ee workpiece waxaa lagu shubi doonaa lakabka zinc.

Zinc waxay dhammaysay farqiga: ma jiro galvanized qabow galvanized kulul galvanized galvanizing muuqaal jilicsan, laakiin dhumucda daahan zinc ee dhinacyada galvanizing qabow ee galvanizing kulul-muquufin waa dhowr jeer. Iska caabbinta daxalka galvanized sidoo kale waa dhowr jeer.

Dulmar

Codsiga

Waxaa inta badan loo isticmaalaa qaybaha xoogga iyo cadaadiska, iyo ujeedada guud uumiga, biyaha, gaaska iyo tuubooyinka hawada.

Fasalka ugu weyn

GR.A, GR.B

Qayb Kiimiko ah

| Darajo | Qayb%,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Nooca S (tuubo aan toos ahayn) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca E (tuubo alxanka iska caabin ah) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Nooca F (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Wadarta shantan curiye waa in aanay ka badnaan 1.00%.

B 0.01% kasta oo hoos u dhaca kaarboonka ugu badan, waxa ku jira manganese ugu badnaan waxa loo ogolyahay in uu kordho 0.06%, laakiin ugu badnaan kama badnaan karo 1.35%.

C 0.01% kasta oo hoos u dhaca kaarboonka ugu badan wuxuu u oggolaanayaa ugu badnaan maadada manganese inay korodho 0.06%, laakiin ugu badnaan waa inaanu ka badnayn 1.65%.

Hantida Makaanikada

| shayga | GR.A | GR.B |

| xoogga xajinta, ≥, psi [MPa] Xoogga Wax-soo-saarka, ≥, psi [MPa] Qiyaas 2in.ama 50mm elongation | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Kordhinta ugu yar ee dhererka cabbirka 2in. (50mm) waa in lagu go'aamiyaa qaacidooyinka soo socda:

e=625000(1940)A0.2/U0.9

e = dhererka ugu yar ee cabbirka 2in. (50mm), boqolkiiba waxa lagu soo koobay 0.5% ee ugu dhow;

A = Waxaa la xisaabiyaa iyadoo loo eegayo dhexroorka bannaanka ee la cayimay ee tuubada magaca ama ballaca magaca ee muunadda xajinta iyo dhumucdeeda darbi ee la cayimay, oo lagu soo koobay qaybta ugu dhow ee muunadda xajinta ee 0.01 in.2 (1 mm2), waxaana la barbar dhigayaa 0.75in.2 (500mm2), hadba kii ka yar.

U = la cayimay xoogga xajinta ugu yar, psi (MPa).

B Isku-darka kala duwan ee cabbirrada kala duwan ee shaybaarrada tijaabada xajinta iyo xoogga ugu yar ee la qoray, dhererka ugu yar ee loo baahan yahay ayaa lagu muujiyey Shaxda X4.1 ama Shaxda X4.2, iyadoo loo eegayo ku habboonaanteeda.

Shuruudaha Imtixaanka

Tijaabada xamaasadda, tijaabada foorarsiga, tijaabada hydrostatic, tijaabada korantada ee alxanka oo aan burbursanayn.

Awood-siinta

Awooda Sahayda: 2000 Ton bishiiba Fasalka ASTM A53/A53M-2012 Dhuumaha Bir

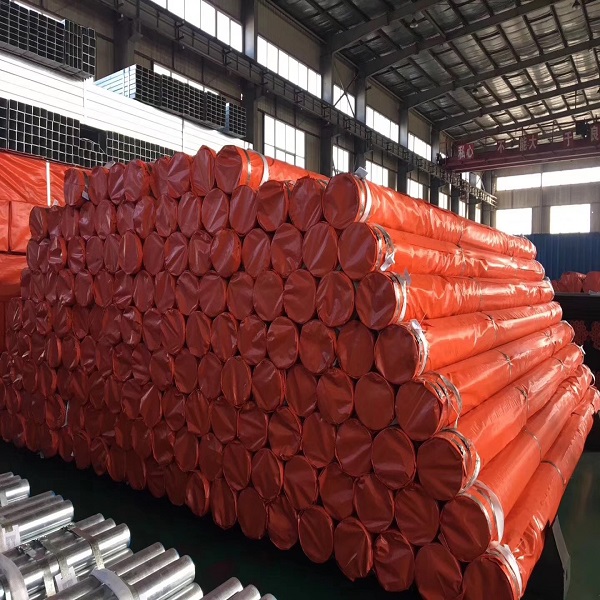

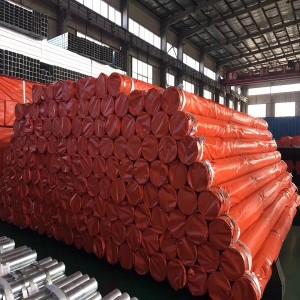

Baakadaha

Xirmooyinka iyo Sanduuqa Alwaaxda ee Xoogan

gaarsiin

7-14 maalmood haddii kaydka, 30-45 maalmood si loo soo saaro

Lacag bixinta

30% deebaaji, 70% L/C ama nuqul B/L ama 100% L/C marka la eego