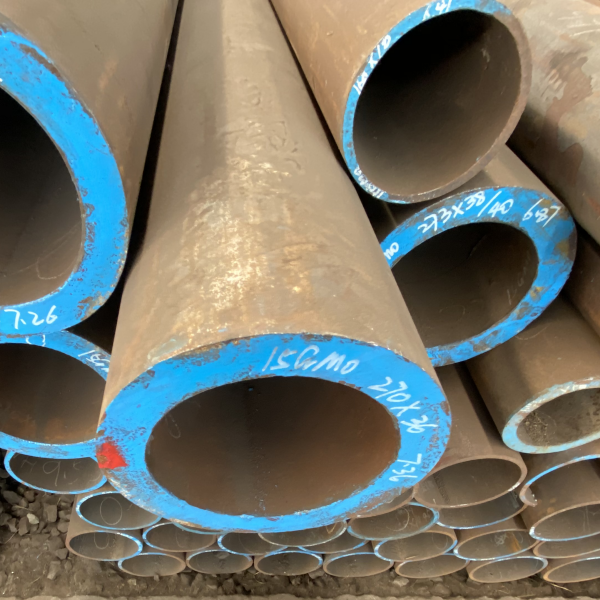

I-18 Years Factory 12cr1movg High Pressure Seamless Boiler Alloy Steel Tubes

Ibhizinisi lethu lihlose ukusebenza ngokwethembeka, ukusebenzela wonke amakhasimende ethu, nokusebenza ngobuchwepheshe obusha nomshini omusha ngokuqhubekayo iminyaka eyi-18 Factory 12cr1movg High Pressure Seamless Boiler Alloy Steel Tubes, Sinamathela ekunikezeni izindlela zokuhlanganisa zabaxhasi futhi sithemba ukwakha isikhathi eside- isikhathi eside, ezinzile, ukwethembeka kanye nobudlelwano obusebenzayo kanye namathemba. Sikubheke ngabomvu ukuvakasha kwakho.

Ibhizinisi lethu lihlose ukusebenza ngokwethembeka, ukusebenzela wonke amakhasimende ethu, nokusebenza ngobuchwepheshe obusha kanye nomshini omusha ngokuqhubekayoIpayipi lensimbi lase-China kanye ne-Casting Tubing, Sithole ukuqashelwa okuningi phakathi kwamakhasimende asabalale emhlabeni wonke. Bayasethemba futhi njalo banikeza imiyalo ephindaphindwayo. Ngaphezu kwalokho, okubalulwe ngezansi ngezinye zezinto ezinkulu ezidlale indima enkulu ekukhuleni kwethu okukhulu kulesi sizinda.

Uhlolojikelele

| Okujwayelekile:I-GB9948-2006 | Ukwelashwa Kokushisa: Ukunciphisa/Ukwejwayelekile/Ukushisa |

| Iqembu leBanga: 10, 12CrMo, 15CrMo, 07Crl9Nil0, njll. | Ububanzi Bangaphandle(Umjikelezo): 10 - 1000 Mm |

| Ubukhulu: 1 - 100 mm | Isicelo: amashubhu okushintshanisa ukushisa |

| Ububanzi Bangaphandle(Umjikelezo): 10 – 1000 mm | Ukwelapha Okungaphezulu: Njengemfuneko Yekhasimende |

| Ubude: Ubude obulungisiwe noma ubude obungahleliwe | Icebo: I-Hot Rolled |

| Ukuma Kwesigaba: Umjikelezo | Ipayipi Elikhethekile: Ipayipi Lodonga Eliwugqinsi |

| Indawo Yomsuka: China | Ukusetshenziswa: amashubhu okushintshanisa ukushisa |

| Isitifiketi: ISO9001:2008 | Isivivinyo:UT/MT |

Isicelo

Amashubhu ensimbi angenamthungo wokuqhekeka kwe-petroleum asebenza kumashubhu ensimbi engenamthungo amashubhu esithandweni somlilo, amashubhu okushintshanisa ukushisa namapayipi okucindezela embonini ye-petrochemical.

Ikhwalithi ephezulu ye-carbon structural steel amabanga angama-20g, 20mng no-25mng.

I-alloy structural steel amamaki: 15mog, 20mog, 12crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, njll

Ibanga Eliyinhloko

Ibanga lensimbi ephezulu ye-carbon structural: 10 #, 20 #

Ikhwalithi ephezulu ye-carbon structural steel amabanga: 20g, 20mng no-25mng

Ingxubevange amamaki ensimbi yesakhiwo: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, njll

Ingxenye Yekhemikhali

| No | Ibanga | Ingxenye Yekhemikhali % | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Insimbi Yesakhiwo Sekhabhoni Esezingeni Eliphezulu | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| I-alloy Structural Steel | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5Mont | |||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9Mont | |||||||||||||

| Insimbi Engangeni Kokushisa Okungagqwali | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9.00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

Impahla Mechanical

| Cha | I-tensile I-MPa | Veza I-MPa | Isikhathi eside ngemva kokuphuka A/% | Amandla okumunca ushaka kv2/j | Inombolo yobulukhuni beBrinell | ||

| isithombe | umdluliseli | isithombe | umdluliseli | ||||

| hhayi ngaphansi kuka | akukho ngaphezu | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5Mont | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9Mont | 590—740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | > 520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | > 520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | > 485 | 170 | 35 | 一 | - | 187 HBW | |

| Ngensimbi enogqinsi olungaphansi kuka-5mm ungawenzi ukuhlolwa kobulukhuni | |||||||

Isidingo Sokuhlola

Ukuhlolwa kwe-hydraulic

Ukuhlolwa kwe-hydraulic kuzokwenziwa kumapayipi ensimbi ngamunye ngamunye. Ingcindezi yokuhlola ephezulu ingu-20 MPa. Ngaphansi kwengcindezi yokuhlola, isikhathi sokuzinza akufanele sibe ngaphansi kwe-10 s, futhi ukuvuza kwepayipi yensimbi akuvunyelwe.

Ukuhlolwa kokucaba

Ukuhlolwa kokucaba kuzokwenziwa ipayipi lensimbi elinobubanzi obungaphezulu kuka-22 mm

Ukuhlolwa kokuvutha

Ikhwalithi ephezulu yensimbi yesakhiwo sekhabhoni kanye namapayipi ensimbi angagqwali (amelana nokushisa) anobubanzi obungaphandle obungeqile ku-76 mm kanye nogqinsi olungeqile ku-8 mm azobhekana nokuhlolwa okukhulayo. Ukuhlolwa kwe-flaring kuzokwenziwa ekamelweni lokushisa. Izinga lokuvuleka kwedayamitha yangaphandle yesampula ngemva kokuba i-top core taper ingu-60% wokuvutha kuzohlangabezana nezidingo zethebula 7. Akukho mifantu noma imifantu evunyelwe kusampula ngemva kokuvutha. Ngokwezidingo zomuntu odingayo futhi eziphawulwe kwinkontileka, insimbi yesakhiwo se-alloy ingase isetshenziselwe ukwandisa ukuhlolwa.

I teste engonakalisi

Amapayipi ensimbi kufanele atholwe amaphutha e-ultrasonic ngalinye ngalinye ngokuvumelana nezinhlinzeko ze-GB / T 5777-2008. Ngokwezidingo zomfakisicelo, ezinye izivivinyo ezingabhubhisi zingangezwa ngemva kwezingxoxo phakathi komphakeli nomfuneli futhi kukhonjiswe kunkontileka.

Ukuhlolwa kokugqwala kwe-Intergranular

Ukuhlolwa kokugqwala kwe-Intergranular kuzokwenziwa ngepayipi lensimbi elingagqwali (elimelana nokushisa). Indlela yokuhlola izohambisana nezinhlinzeko zendlela yesiShayina E ku-GB / T 4334-2008, futhi ukuthambekela kokugqwala kwe-intergranular akuvunyelwe ngemuva kokuhlolwa.

Ngemuva kwezingxoxo phakathi komphakeli kanye nomfunayo, futhi kuphawulwe kwinkontileka, lowo odingayo angaqoka ezinye izindlela zokuhlola ukugqwala.

Imininingwane Yomkhiqizo

mechanical/Chemical & Fertilizer Amapayipi

I-GB/T8162-2008

ASTM_A519-2006

I-BS EN 10210-1-2006

I-ASTM A53A53M-2012

I-GB9948-2006

I-GB6479-2013

I-GB/T 17396-2009

Ibhizinisi lethu lihlose ukusebenza ngokwethembeka, ukusebenzela wonke amakhasimende ethu, nokusebenza ngobuchwepheshe obusha nomshini omusha ngokuqhubekayo iminyaka eyi-18 Factory 12cr1movg High Pressure Seamless Boiler Alloy Steel Tubes, Sinamathela ekunikezeni izindlela zokuhlanganisa zabaxhasi futhi sithemba ukwakha isikhathi eside- isikhathi eside, ezinzile, ukwethembeka kanye nobudlelwano obusebenzayo kanye namathemba. Sikubheke ngabomvu ukuvakasha kwakho.

Iminyaka engu-18 FactoryIpayipi lensimbi lase-China kanye ne-Casting Tubing, Sithole ukuqashelwa okuningi phakathi kwamakhasimende asabalale emhlabeni wonke. Bayasethemba futhi njalo banikeza imiyalo ephindaphindwayo. Ngaphezu kwalokho, okubalulwe ngezansi ngezinye zezinto ezinkulu ezidlale indima enkulu ekukhuleni kwethu okukhulu kulesi sizinda.

Uwoyela, i-petrochemical, i-high pressure boiler, ukusetshenziswa okukhethekile kweshubhu elingenamthungo likabhoyili elingenamthungo, ishubhu lensimbi elingenamthungo le-geological kanye neshubhu yamafutha engenamthungo.

Ingxenye Yekhemikhali

| uphawu | Ingxenye Yekhemikhali (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12~0.18 | 0.40~0,70 | 0.17~0.37 | 0.80~1.10 | 0.40~0,55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Impahla Mechanical

| uphawu | I-tensile I-MPa | Veza I-MPa | Ubude (%) |

| 15CrMo | 440 ~ 640 | 295 | 22 |