Seamless steel pipe for machinery-ASTM A519 4140

Seamless steel pipe for machinery-ASTM A519 4140,

alloy steel pipe, Mechanical tubes, seamless steel pipe,

Overview

Application

It Is Mainly Used for mechanical and used to make gas cylinders.

Main Grade

1018,1026,8620,4130,4140

Chemical Component

TABLE 1 Chemical Requirements of Low-Carbon Steels

| Grade | Chemical Composition Limits, % | |||||||

| Designation | CarbonA | ManganeseB | Phosphorus,B | Sulfur,B | ||||

| max | max | |||||||

| MT X 1015 | 0.10–0.20 | 0.60–0.90 | 0.04 | 0.05 | ||||

| MT 1010 | 0.05–0.15 | 0.30–0.60 | 0.04 | 0.05 | ||||

| MT 1015 | 0.10–0.20 | 0.30–0.60 | 0.04 | 0.05 | ||||

| MT 1020 | 0.15–0.25 | 0.30–0.60 | 0.04 | 0.05 | ||||

| MT X 1020 | 0.15–0.25 | 0.70–1.00 | 0.04 | 0.05 | ||||

B Limits apply to heat analysis; except as required by 6.1, product analyses are subject to the applicable additional tolerances given in Table 5.

TABLE 2 Chemical Requirements of Other Carbon Steels

|

Grade |

Chemical Composition Limits, %A |

||||

|

Designation |

|||||

|

Carbon |

Manganese |

Phosphorus, |

Sulfur, |

||

|

max |

max |

||||

|

1008 |

0.10 max |

0.30–0.50 |

0.040 |

0.050 |

|

|

1010 |

0.08–0.13 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1012 |

0.10–0.15 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1015 |

0.13–0.18 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1016 |

0.13–0.18 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1017 |

0.15–0.20 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1018 |

0.15–0.20 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1019 |

0.15–0.20 |

0.70–1.00 |

0.040 |

0.050 |

|

|

1020 |

0.18–0.23 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1021 |

0.18–0.23 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1022 |

0.18–0.23 |

0.70–1.00 |

0.040 |

0.050 |

|

|

1025 |

0.22–0.28 |

0.30–0.60 |

0.040 |

0.050 |

|

|

1026 |

0.22–0.28 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1030 |

0.28–0.34 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1035 |

0.32–0.38 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1040 |

0.37–0.44 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1045 |

0.43–0.50 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1050 |

0.48–0.55 |

0.60–0.90 |

0.040 |

0.050 |

|

|

1518 |

0.15–0.21 |

1.10–1.40 |

0.040 |

0.050 |

|

|

1524 |

0.19–0.25 |

1.35–1.65 |

0.040 |

0.050 |

|

|

1541 |

0.36–0.44 |

1.35–1.65 |

0.040 |

0.050 |

|

A The ranges and limits given in this table apply to heat analysis; except as required by 6.1, product analyses are subject to the applicable additional toler-ances given in Table Number 5.

|

TABLE 3 Chemical Requirements for Alloy Steels |

|||||||||

|

NOTE |

1—The ranges and limits in this table apply to steel not exceeding 200 in.2 (1290 cm2) in cross-sectional area. |

||||||||

|

NOTE |

2—Small quantities of certain elements are present in alloy steels which are not specified or required. These elements are considered as incidental |

||||||||

|

and may be present to the following maximum amounts: copper, 0.35 %; nickel, 0.25 %; chromium, 0.20 %; molybdenum, 0.10 %. |

|||||||||

|

NOTE |

3—The ranges and limits given in this table apply to heat analysis; except as required by 6.1, product analyses are subject to the applicable |

||||||||

|

additional tolerances given in Table Number 5. |

|||||||||

| GradeA,B | Chemical Composition Limits, % | |||||||

| Designa- | ||||||||

| Carbon | Manganese | Phospho- | Sulfur,C,D | Silicon | Nickel | Chromium | Molybde- | |

| tion | ||||||||

| rus,Cmax | max | num | ||||||

| 1330 | 0.28–0.33 | 1.60–1.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | … |

| 1335 | 0.33–0.38 | 1.60–1.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | … |

| 1340 | 0.38–0.43 | 1.60–1.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | … |

| 1345 | 0.43–0.48 | 1.60–1.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | … |

| 3140 | 0.38–0.43 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 1.10–1.40 | 0.55–0.75 | … |

| E3310 | 0.08–0.13 | 0.45–0.60 | 0.025 | 0.025 | 0.15–0.35 | 3.25–3.75 | 1.40–1.75 | … |

| 4012 | 0.09–0.14 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.15–0.25 |

| 4023 | 0.20–0.25 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4024 | 0.20–0.25 | 0.70–0.90 | 0.04 | 0.035−0.050 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4027 | 0.25–0.30 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4028 | 0.25–0.30 | 0.70–0.90 | 0.04 | 0.035−0.050 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4037 | 0.35–0.40 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4042 | 0.40–0.45 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4047 | 0.45–0.50 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4063 | 0.60–0.67 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.20–0.30 |

| 4118 | 0.18–0.23 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.40–0.60 | 0.08–0.15 |

| 4130 | 0.28–0.33 | 0.40–0.60 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4135 | 0.32–0.39 | 0.65–0.95 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4137 | 0.35–0.40 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4140 | 0.38–0.43 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4142 | 0.40–0.45 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4145 | 0.43–0.48 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4147 | 0.45–0.50 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4150 | 0.48–0.53 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15–0.25 |

| 4320 | 0.17–0.22 | 0.45–0.65 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | 0.40–0.60 | 0.20–0.30 |

| 4337 | 0.35–0.40 | 0.60–0.80 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | 0.70–0.90 | 0.20–0.30 |

| E4337 | 0.35–0.40 | 0.65–0.85 | 0.025 | 0.025 | 0.15–0.35 | 1.65–2.00 | 0.70–0.90 | 0.20–0.30 |

| 4340 | 0.38–0.43 | 0.60–0.80 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | 0.70–0.90 | 0.20–0.30 |

| E4340 | 0.38–0.43 | 0.65–0.85 | 0.025 | 0.025 | 0.15–0.35 | 1.65–2.00 | 0.70–0.90 | 0.20–0.30 |

| 4422 | 0.20–0.25 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.35–0.45 |

| 4427 | 0.24–0.29 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.35–0.45 |

| 4520 | 0.18–0.23 | 0.45–0.65 | 0.04 | 0.04 | 0.15–0.35 | … | … | 0.45–0.60 |

| 4615 | 0.13–0.18 | 0.45–0.65 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | … | 0.20–0.30 |

| 4617 | 0.15–0.20 | 0.45–0.65 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | … | 0.20–0.30 |

| 4620 | 0.17–0.22 | 0.45–0.65 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | … | 0.20–0.30 |

| 4621 | 0.18–0.23 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 1.65–2.00 | … | 0.20–0.30 |

| 4718 | 0.16–0.21 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.90–1.20 | 0.35–0.55 | 0.30–0.40 |

| 4720 | 0.17–0.22 | 0.50–0.70 | 0.04 | 0.04 | 0.15–0.35 | 0.90–1.20 | 0.35–0.55 | 0.15–0.25 |

| 4815 | 0.13–0.18 | 0.40–0.60 | 0.04 | 0.04 | 0.15–0.35 | 3.25–3.75 | … | 0.20–0.30 |

| 4817 | 0.15–0.20 | 0.40–0.60 | 0.04 | 0.04 | 0.15–0.35 | 3.25–3.75 | … | 0.20–0.30 |

| 4820 | 0.18–0.23 | 0.50–0.70 | 0.04 | 0.04 | 0.15–0.35 | 3.25–3.75 | … | 0.20–0.30 |

| 5015 | 0.12–0.17 | 0.30–0.50 | 0.04 | 0.04 | 0.15–0.35 | … | 0.30–0.50 | … |

| 5046 | 0.43–0.50 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.20–0.35 | … |

| 5115 | 0.13–0.18 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5120 | 0.17–0.22 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5130 | 0.28–0.33 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | … |

| 5132 | 0.30–0.35 | 0.60–0.80 | 0.04 | 0.04 | 0.15–0.35 | … | 0.75–1.00 | … |

| 5135 | 0.33–0.38 | 0.60–0.80 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.05 | … |

| 5140 | 0.38–0.43 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5145 | 0.43–0.48 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5147 | 0.46–0.51 | 0.70–0.95 | 0.04 | 0.04 | 0.15–0.35 | … | 0.85–1.15 | … |

| 5150 | 0.48–0.53 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5155 | 0.51–0.59 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 5160 | 0.56–0.64 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 52100E | 0.93–1.05 | 0.25–0.45 | 0.025 | 0.015 | 0.15–0.35 | 0.25 max | 1.35–1.60 | 0.10 max |

| E50100 | 0.98–1.10 | 0.25–0.45 | 0.025 | 0.025 | 0.15–0.35 | … | 0.40–0.60 | … |

| E51100 | 0.98–1.10 | 0.25–0.45 | 0.025 | 0.025 | 0.15–0.35 | … | 0.90–1.15 | … |

| E52100 | 0.98–1.10 | 0.25–0.45 | 0.025 | 0.025 | 0.15–0.35 | … | 1.30–1.60 | … |

| Vanadium | ||||||||

| 6118 | 0.16–0.21 | 0.50–0.70 | 0.04 | 0.04 | 0.15–0.35 | … | 0.50–0.70 | 0.10–0.15 |

| 6120 | 0.17–0.22 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | 0.10 min |

| 6150 | 0.48–0.53 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | … | 0.80–1.10 | 0.15 min |

| Aluminum | Molybdenum | |||||||

| E7140 | 0.38–0.43 | 0.50–0.70 | 0.025 | 0.025 | 0.15–0.40 | 0.95–1.30 | 1.40–1.80 | 0.30–0.40 |

| Nickel | ||||||||

| 8115 | 0.13–0.18 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.20–0.40 | 0.30–0.50 | 0.08–0.15 |

| 8615 | 0.13–0.18 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8617 | 0.15–0.20 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8620 | 0.18–0.23 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8622 | 0.20–0.25 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8625 | 0.23–0.28 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8627 | 0.25–0.30 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8630 | 0.28–0.33 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8637 | 0.35–0.40 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8640 | 0.38–0.43 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8642 | 0.40–0.45 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8645 | 0.43–0.48 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8650 | 0.48–0.53 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8655 | 0.51–0.59 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8660 | 0.55–0.65 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 8720 | 0.18–0.23 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.20–0.30 |

| 8735 | 0.33–0.38 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.20–0.30 |

| 8740 | 0.38–0.43 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.20–0.30 |

| 8742 | 0.40–0.45 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.20–0.30 |

| 8822 | 0.20–0.25 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.30–0.40 |

| 9255 | 0.51–0.59 | 0.60–0.80 | 0.04 | 0.04 | 1.80–2.20 | … | 0.60–0.80 | … |

| 9260 | 0.56–0.64 | 0.75–1.00 | 0.04 | 0.04 | 1.80–2.20 | … | … | … |

| 9262 | 0.55–0.65 | 0.75–1.00 | 0.04 | 0.04 | 1.80–2.20 | … | 0.25–0.40 | … |

| E9310 | 0.08–0.13 | 0.45–0.65 | 0.025 | 0.025 | 0.15–0.35 | 3.00–3.50 | 1.00–1.40 | 0.08–0.15 |

| 9840 | 0.38–0.42 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.85–1.15 | 0.70–0.90 | 0.20–0.30 |

| 9850 | 0.48–0.53 | 0.70–0.90 | 0.04 | 0.04 | 0.15–0.35 | 0.85–1.15 | 0.70–0.90 | 0.20–0.30 |

| 50B40 | 0.38–0.42 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.40–0.60 | … |

| 50B44 | 0.43–0.48 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.40–0.60 | … |

| 50B46 | 0.43–0.50 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.20–0.35 | … |

| 50B50 | 0.48–0.53 | 0.74–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.40–0.60 | … |

| 50B60 | 0.55–0.65 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.40–0.60 | … |

| 51B60 | 0.56–0.64 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | … | 0.70–0.90 | … |

| 81B45 | 0.43–0.48 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.20–0.40 | 0.35–0.55 | 0.08–0.15 |

| 86B45 | 0.43–0.48 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.40–0.70 | 0.40–0.60 | 0.15–0.25 |

| 94B15 | 0.13–0.18 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.30–0.60 | 0.30–0.50 | 0.08–0.15 |

| 94B17 | 0.15–0.20 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.30–0.60 | 0.30–0.50 | 0.08–0.15 |

| 94B30 | 0.28–0.33 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.30–0.60 | 0.30–0.50 | 0.08–0.15 |

| 94B40 | 0.38–0.43 | 0.75–1.00 | 0.04 | 0.04 | 0.15–0.35 | 0.30–0.60 | 0.30–0.50 | 0.08–0.15 |

B Grades shown in this table with the letter B, such as 50B40, can be expected to have 0.0005 % minimum boron control. A Grades shown in this table with prefix letter E generally are manufactured by the basic-electric-furnace process. All others are normally manufactured by the basic-open-hearth process but may be manufactured by the basic-electric-furnace process with adjustments in phosphorus and sulfur.

C The phosphorus sulfur limitations for each process are as follows:

Basic electric furnace 0.025 max % Acid electric furnace 0.050 max %

Basic open hearth 0.040 max % Acid open hearth 0.050 max %

D Minimum and maximum sulfur content indicates resulfurized steels.

EThe purchaser may specify the following maximum amounts: copper, 0.30 %; aluminum, 0.050 %; and oxygen, 0.0015 %.

Mechanical Property

Typical Tensile Properties, Hardness and Thermal Condition for some of the More Common Grades of Carbon and Alloy Steels

CW—Cold Worked SR—Stress Relieved A—Annealed N—NormalizedA The following are the symbol definitions for the various conditions: HR—Hot Rolle

| Grade | Condi- | Ultimate | Yield | Elongation | Rockwell, | ||||

| Desig- | tionA | Strength, | Strength, | in 2 in. or | Hardness | ||||

| nation | 50 mm, % | B Scale | |||||||

| ksi | MPa | ksi | MPa | ||||||

| 1020 | HR | 50 | 345 | 32 | 221 | 25 | 55 | ||

| CW | 70 | 483 | 60 | 414 | 5 | 75 | |||

| SR | 65 | 448 | 50 | 345 | 10 | 72 | |||

| A | 48 | 331 | 28 | 193 | 30 | 50 | |||

| N | 55 | 379 | 34 | 234 | 22 | 60 | |||

| 1025 | HR | 55 | 379 | 35 | 241 | 25 | 60 | ||

| CW | 75 | 517 | 65 | 448 | 5 | 80 | |||

| SR | 70 | 483 | 55 | 379 | 8 | 75 | |||

| A | 53 | 365 | 30 | 207 | 25 | 57 | |||

| N | 55 | 379 | 36 | 248 | 22 | 60 | |||

| 1035 | HR | 65 | 448 | 40 | 276 | 20 | 72 | ||

| CW | 85 | 586 | 75 | 517 | 5 | 88 | |||

| SR | 75 | 517 | 65 | 448 | 8 | 80 | |||

| A | 60 | 414 | 33 | 228 | 25 | 67 | |||

| N | 65 | 448 | 40 | 276 | 20 | 72 | |||

| 1045 | HR | 75 | 517 | 45 | 310 | 15 | 80 | ||

| CW | 90 | 621 | 80 | 552 | 5 | 90 | |||

| SR | 80 | 552 | 70 | 483 | 8 | 85 | |||

| A | 65 | 448 | 35 | 241 | 20 | 72 | |||

| N | 75 | 517 | 48 | 331 | 15 | 80 | |||

| 1050 | HR | 80 | 552 | 50 | 345 | 10 | 85 | ||

| SR | 82 | 565 | 70 | 483 | 6 | 86 | |||

| A | 68 | 469 | 38 | 262 | 18 | 74 | |||

| N | 78 | 538 | 50 | 345 | 12 | 82 | |||

| 1118 | HR | 50 | 345 | 35 | 241 | 25 | 55 | ||

| CW | 75 | 517 | 60 | 414 | 5 | 80 | |||

| SR | 70 | 483 | 55 | 379 | 8 | 75 | |||

| A | 50 | 345 | 30 | 207 | 25 | 55 | |||

| N | 55 | 379 | 35 | 241 | 20 | 60 | |||

| 1137 | HR | 70 | 483 | 40 | 276 | 20 | 75 | ||

| CW | 80 | 552 | 65 | 448 | 5 | 85 | |||

| SR | 75 | 517 | 60 | 414 | 8 | 80 | |||

| A | 65 | 448 | 35 | 241 | 22 | 72 | |||

| N | 70 | 483 | 43 | 296 | 15 | 75 | |||

| 4130 | HR | 90 | 621 | 70 | 483 | 20 | 89 | ||

| SR | 105 | 724 | 85 | 586 | 10 | 95 | |||

| A | 75 | 517 | 55 | 379 | 30 | 81 | |||

| N | 90 | 621 | 60 | 414 | 20 | 89 | |||

| 4140 | HR | 120 | 855 | 90 | 621 | 15 | 100 | ||

| SR | 120 | 855 | 100 | 689 | 10 | 100 | |||

| A | 80 | 552 | 60 | 414 | 25 | 85 | |||

| N | 120 | 855 | 90 | 621 | 20 | 100 | |||

d

Test Requirement

Hardness Test,Tension Tests, Nondestructive Tests,Steel Cleanliness, Hardenability, Flaring Test

Supply Ability

Supply Ability: 2000 Tons Per Month Per Grade Of ASTM A519-2006 Steel Pipe

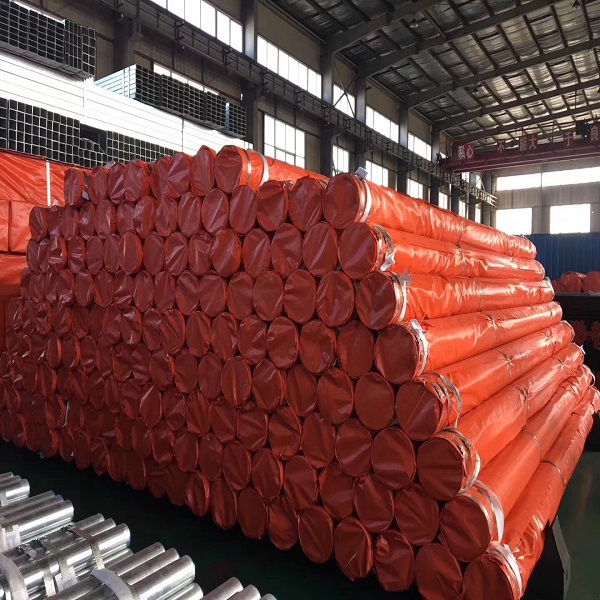

Packaging

In Bundles And In Strong Wooden Box

Delivery

7-14 days if in stock, 30-45 days to produce

Payment

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight