Hale Hana Makai Kina High Quality Pololei Carbon Steel Welded Paipu

Nānā nui

"E hoʻomalu i ka maʻamau e nā kiko'ī, e hōʻike i ka ikehu ma ka maikaʻi". Ua hoʻoikaika kā mākou ʻoihana e hoʻokumu i kahi limahana limahana kūpono a kūpaʻa a ʻimi i kahi kaʻina hana hoʻomalu maikaʻi maikaʻi no Straight Carbon Steel Welded Pipes. ʻO ka maikaʻi maikaʻi ke ola o ka hale hana, ʻo ka nānā ʻana i ka noi o ka mea kūʻai aku ke kumu o ke ola ʻana o ka ʻoihana a me ka holomua, Hoʻopili mākou i ka ʻoiaʻiʻo a me ka manaʻoʻiʻo maikaʻi e hana nei, e ʻimi ana i mua i kou hele ʻana mai!

No ka paipu kila kalapona welded, aia he 2 ʻenehana nui e pono e hoʻomaopopo ʻo ia ʻo ERW (electric resistance weld) a me SAW (submerge arc weld). Hoʻohana nui ʻia nā paipu i kēia ʻenehana no ka ʻoihana ʻaila no ka lawe ʻana i ka aila a me ke kinoea, akā loaʻa iā lākou āpau ko lākou pono ponoʻī, no laila ʻano ʻokoʻa ka hoʻohana ʻana.

Hana ʻia ka paipu ERW mai ka pā kila, hoʻokahi wale nō seam welded, a no ka mea i hele mai ka laina welded o ka paipu ERW mai ka paipu makuahine, ʻaʻole pono ka solder flux, no laila maikaʻi ka waiwai mechanical. A ma muli o kona mau hiʻohiʻona o ka hana kiʻekiʻe, ke kumu kūʻai haʻahaʻa, ka mālama waiwai, a me ka maʻalahi automation, e hoʻohālikelike me ka paipu SAW, ʻo ka paipu ERW he paipu kila me ka hana huahana kiʻekiʻe, alakaʻi i ka maikaʻi a me ka hoʻokele waiwai ma ke kahua o ka mālama ʻana i ka aila a me ke kinoea. a me ka halihali ana. E hahai pono i ka ulu ʻana o ka ʻenehana, ʻoi aku ka maikaʻi inā ʻoi aku ka maikaʻi o ka laina welded, ma o ka hoʻohana ʻana i ka ʻenehana hou, ʻo ke kumu e hoʻopau i ke kaumaha, hoʻomaʻemaʻe a hoʻomaʻemaʻe i ke ʻano, a hoʻomaikaʻi i nā ʻano mechanical piha o ka welding wela i hoʻopilikia ʻia. ʻAʻole hiki ke hoʻokaʻawale ʻia kēia ʻano paipu ERW ʻaʻole wale i ka weld, akā hiki i ka coefficient weld ke hiki i ka 1, ka mea e ʻike ai i ka hoʻohālikelike ʻana o ka hale weld me ka mea kumu.

He kiʻekiʻe loa ka nui o ka ʻenehana SAW i kēia manawa, a ʻo ka papa flux e pale i ka nalowale o ka wela a hoʻopaʻa ʻia i loko o ka wahi kūʻai. He kiʻekiʻe ke kiʻekiʻe o ka weld arc welding, ʻaʻohe kukui arc a me ka uahi liʻiliʻi. Hoʻohana nui ʻia nā paipu kila i hoʻoheheʻe ʻia i loko o nā moku kaomi, nā paipu paipu, nā kaola, nā kolamu, nā wai haʻahaʻa haʻahaʻa, a me nā papahana hana kila. Akā ma ka ʻoihana ʻaila ʻāina i kūkulu ʻia, ʻaʻole ʻae ʻia ka paipu SAW no ka mea ka palena o ia iho, aia wale nō ma Kina SAW paipu e ʻae ʻia i ka ʻoihana ʻaila me ka palena.

ʻO ka maikaʻi maikaʻi a me ke kumukūʻai kūpono "ʻo kā mākou mau ʻoihana ʻoihana. Inā makemake ʻoe i kā mākou huahana a me nā hoʻonā a i ʻole he nīnau, e ʻoluʻolu e hoʻokaʻaʻike mai iā mākou. Manaʻo mākou e hoʻokumu i nā pilina pili me ʻoe i ka wā e hiki mai ana.

Palapala noi

Hoʻohana nui ʻia ia no nā ʻāpana ikaika a me nā ʻāpana, a no ke kumu nui o ka mahu, ka wai, ke kinoea a me nā paipu ea.

Papa Nui

GR.A, GR.B

Mea Kimia

| Papa | Huina %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| ʻAno S (paipu ʻole) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ʻAno E | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ʻAno F(Furnace Welded Paipu) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

ʻAʻole ʻoi aku ka nui o kēia mau mea ʻelima ma mua o 1.00%.

B No kēlā me kēia 0.01% ka emi ʻana o ka nui o ka carbon content, ʻae ʻia ka nui o ka manganese e hoʻonui i ka 0.06%, akā ʻaʻole hiki ke kiʻekiʻe ma mua o 1.35%.

C ʻO kēlā me kēia 0.01% ka emiʻana o ke kalapona kalapona kiʻekiʻe eʻae i ka nui o ka manganese e hoʻonui i ka 0.06%, akā,ʻaʻole pono ka nui ma mua o 1.65%.

Waiwai Mekani

| mea | GR.A | GR.B |

| ikaika uʻi, ≥, psi [MPa] Ka ikaika o ka hua, ≥, psi [MPa] Ana 2in. a i ʻole 50mm elongation | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A ʻO ka lōʻihi liʻiliʻi o ka lōʻihi 2in. (50mm) e hoʻoholo ʻia e kēia ʻano kumu:

e=625000(1940)A0.2/U0.9

e = ka lōʻihi liʻiliʻi o ka anana 2in. (50mm), ka pākēneka i hoʻopuni ʻia i ka 0.5% kokoke loa;

A = helu ʻia e like me ke anawaena o waho o ka paipu inoa a i ʻole ka laula inoa o ka hāpana tensile a me kona mānoanoa pā i kuhikuhi ʻia, a hoʻopuni ʻia i kahi kokoke loa o ka hāpana tensile o 0.01 in.2 (1 mm2), a Hoʻohālikelike ʻia me 0.75in.2 (500mm2), ʻoi aku ka liʻiliʻi.

U = ka ikaika tensile palena iki, psi (MPa).

B No nā hui like ʻole o nā nui like ʻole o nā hōʻike hoʻāʻo tensile a me ka ikaika tensile haʻahaʻa i kuhikuhi ʻia, hōʻike ʻia ka elongation haʻahaʻa i koi ʻia ma ka Papa X4.1 a i ʻole ka Papa X4.2, e like me kona kūpono.

Koi hoao

ʻO ka hoʻāʻo tensile, ka hoʻāʻo ʻana, ka hoʻāʻo hydrostatic, ka hoʻāʻo uila nondestructive o nā welds.

Hiki ke hoolako

Hiki ke hoʻolako: 2000 Tons i kēlā me kēia mahina no ka papa o ASTM A53 / A53M-2012 Steel Pipe

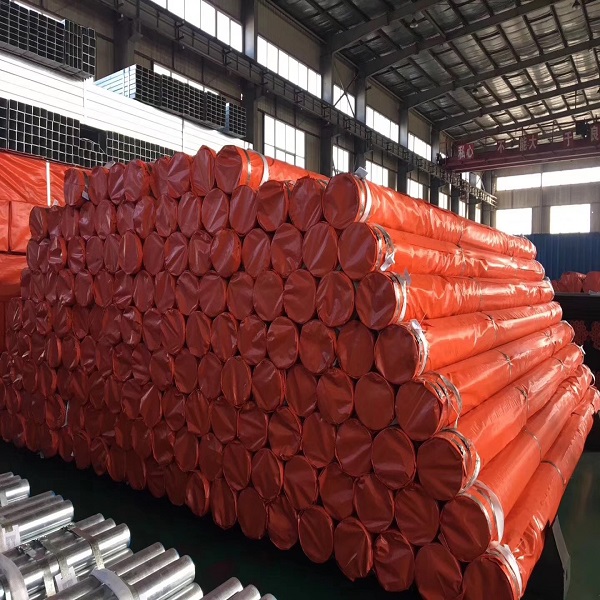

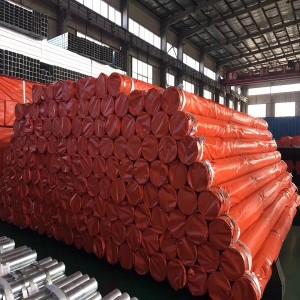

Hoʻopili ʻia

I loko o nā pūʻolo a i loko o ka pahu lāʻau ikaika

Hāʻawi

7-14 mau lā inā ma ka waihona, 30-45 mau lā e hana ai

Uku

30% depsoit, 70% L/C a i ʻole B/L kope a i ʻole 100% L/C i ka ʻike