GB8162 and GB8163 are two different specifications for seamless steel pipes in China's national standards. They have significant differences in use, technical requirements, inspection standards, etc. The following is a detailed comparison of the main differences:

1. Standard name and scope of application

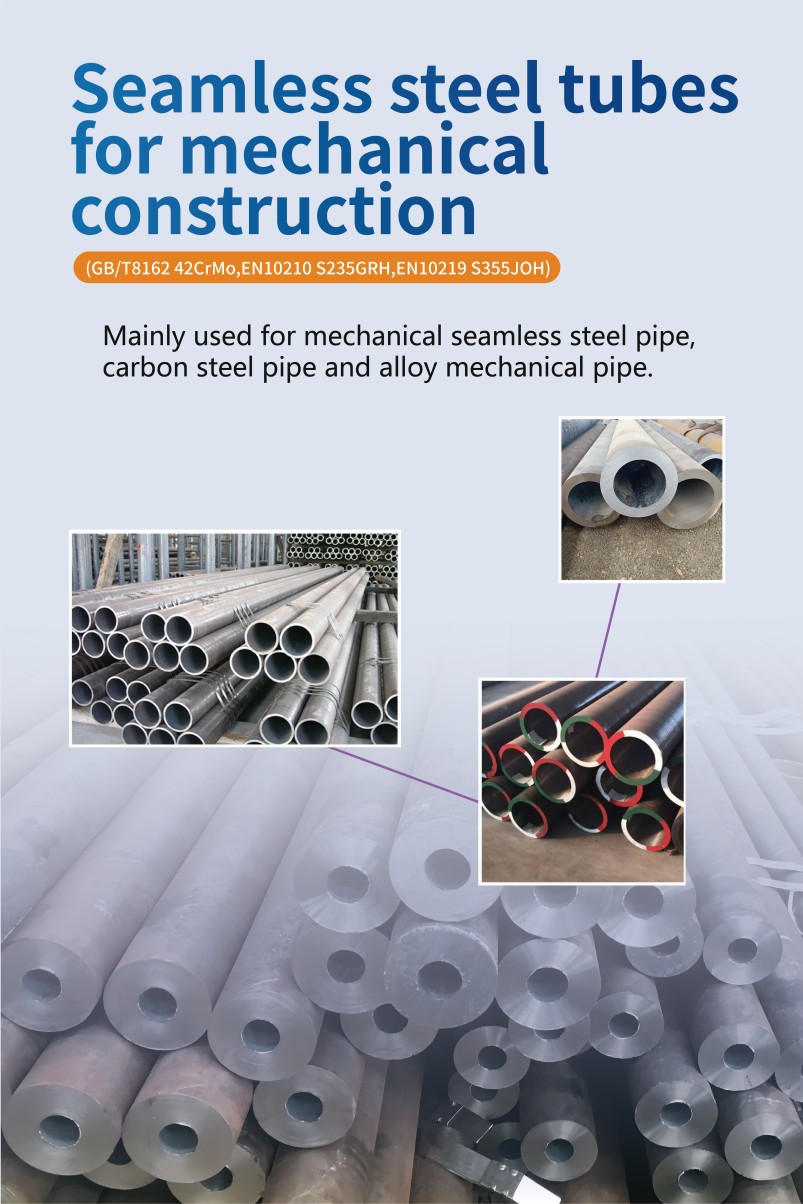

Name: "Seamless Steel Pipe for Structural Use"

Use: Mainly used in general structures, mechanical processing and other non-fluid transportation fields, such as building supports, mechanical parts, etc.

Applicable scenarios: occasions with static or mechanical loads, not suitable for high pressure or fluid transportation.

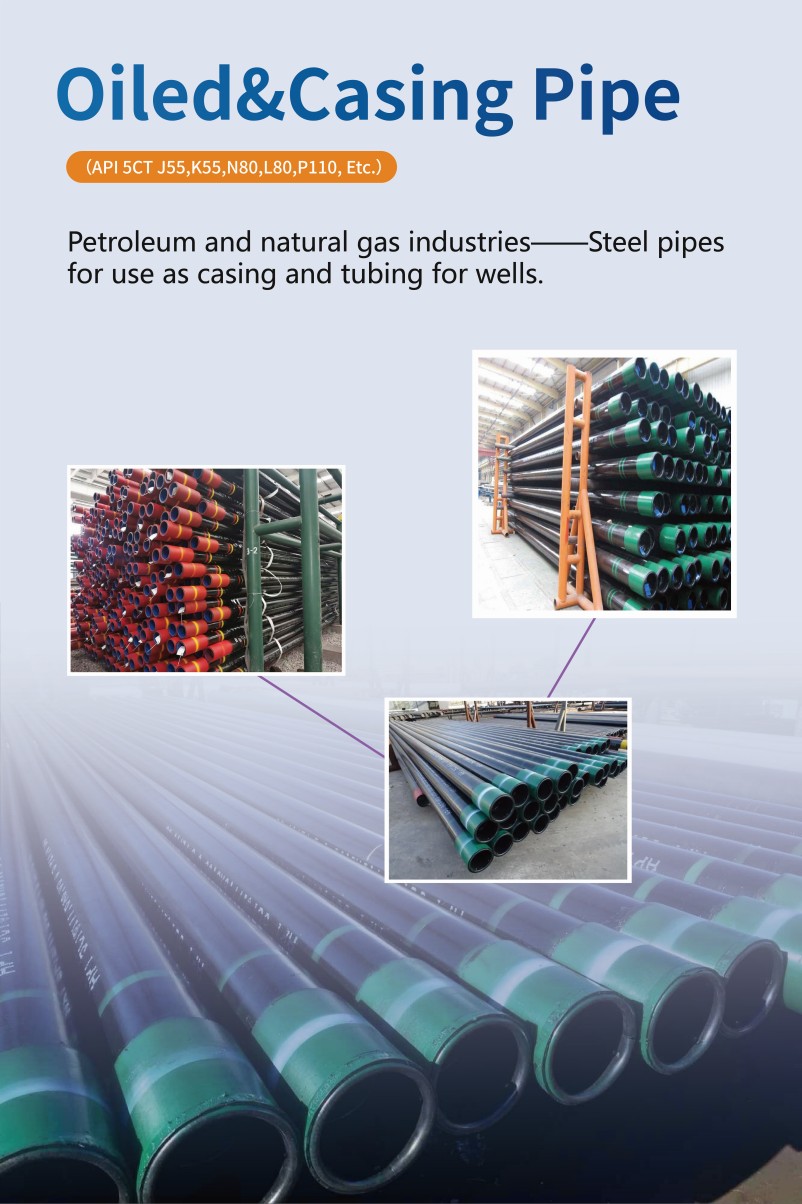

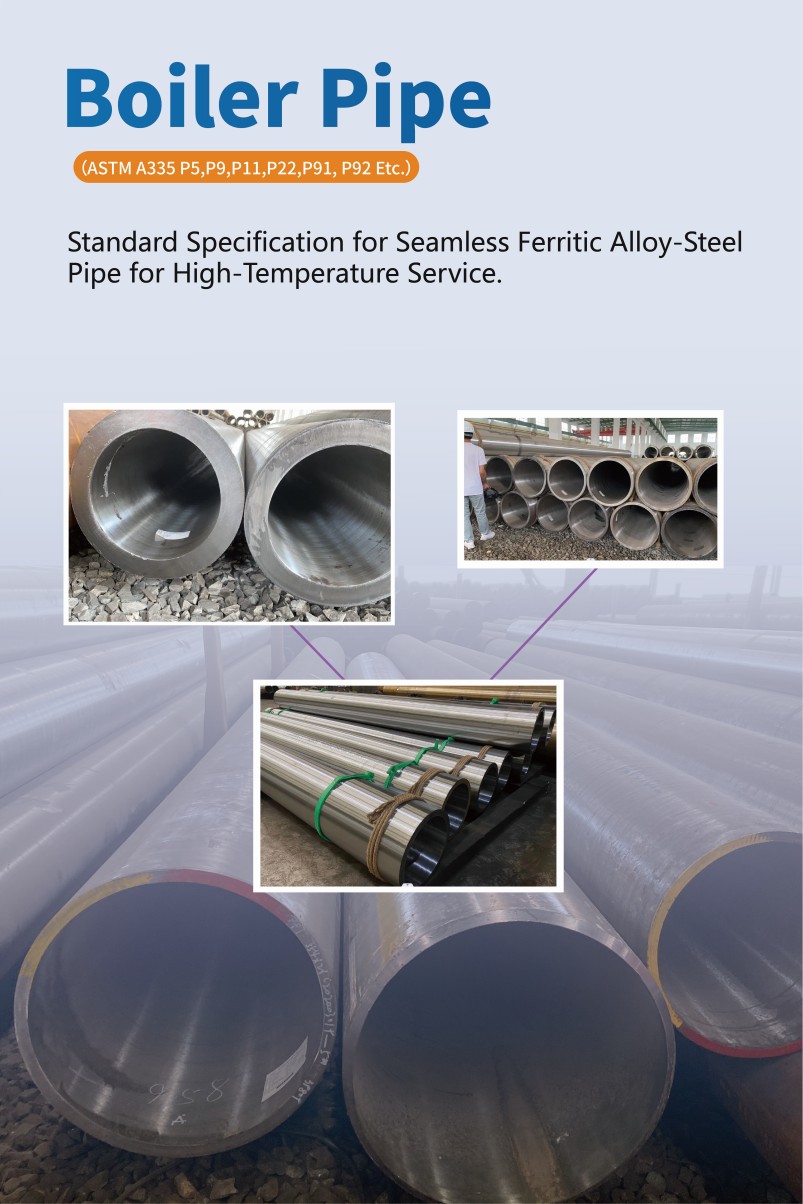

Name: "Seamless Steel Pipe for Fluid Transportation"

Use: Designed for conveying fluids (such as water, oil, gas, etc.), commonly used in pressure pipeline systems such as petroleum, chemical, boilers, etc.

Applicable scenarios: Need to withstand certain pressures and temperatures, and have high safety requirements

2. Material and chemical composition

GB8162:

Common materials: 20#, 45#, Q345B and other ordinary carbon steel or low alloy steel.

The chemical composition requirements are relatively loose, focusing on mechanical properties (such as tensile strength, yield strength).

GB8163:

Common materials: 20#, 16Mn, Q345B, etc., good weldability and pressure resistance must be guaranteed.

The content of harmful elements such as sulfur (S) and phosphorus (P) is more strictly controlled to ensure the safety of fluid transportation.

3. Mechanical performance requirements

GB8162:

Focus on mechanical properties such as tensile strength and elongation to meet the structural load-bearing requirements.

Impact toughness or high temperature performance tests are usually not required.

GB8163:

In addition to tensile strength, water pressure tests, expansion tests, flattening tests, etc. may be required to ensure that the steel pipe has no leakage or deformation under pressure.

Some working conditions require additional high temperature performance or low temperature impact tests.

4. Pressure test

GB8162:

Hydraulic pressure test is usually not mandatory (unless agreed in the contract).

GB8163:

Hydraulic pressure test (or non-destructive testing) must be carried out to verify the pressure bearing capacity.

5. Manufacturing process and inspection

GB8162:

The production process (hot rolling, cold drawing) can meet the general structural requirements.

There are fewer inspection items, usually including size, surface quality, and mechanical properties.

GB8163:

The production process needs to ensure higher uniformity and density (such as continuous casting or refining outside the furnace).

The inspection is more stringent, including non-destructive testing such as eddy current testing and ultrasonic testing (depending on the purpose).

6. Marking and certification

GB8162: The standard number, material, specification, etc. must be marked in the mark, but there is no special certification requirement.

GB8163: Additional pressure pipeline-related certification (such as special equipment license) may be required.

Note:

Mixing is strictly prohibited: GB8163 steel pipes can be used for structural purposes (must comply with GB8162 requirements), but GB8162 steel pipes cannot replace GB8163 for fluid transportation, otherwise there will be safety hazards.

Post time: Apr-14-2025