I. Khoom Muag Khoom

GB/T9948-2013seamless steel yeeb nkab yog cov yeeb nkab zoo seamless steel tshwj xeeb uas siv rau cov txheej txheem roj av tawg, thiab yog siv dav hauv cov cuab yeej tseem ceeb xws li cov kav hlau, cov cua sov thiab cov kav dej hauv cov roj refineries. Cov txheej txheem no nruj me ntsis tswj cov khoom siv, kev tsim khoom thiab kev ua haujlwm ntawm cov kav hlau steel kom ntseeg tau tias lawv cov haujlwm ruaj khov hauv cov khoom siv hluav taws xob siab, kub-kub thiab siab-siab ib puag ncig.

2. Cov khoom siv thiab kev ua haujlwm

1. Cov ntaub ntawv tseem ceeb

GB/T9948-2013seamless steel kav yog tsim los ntawm ntau yam khoom siv hlau zoo, suav nrog:

Carbon steel qauv:20 G, 20 MnG, 25 MnG

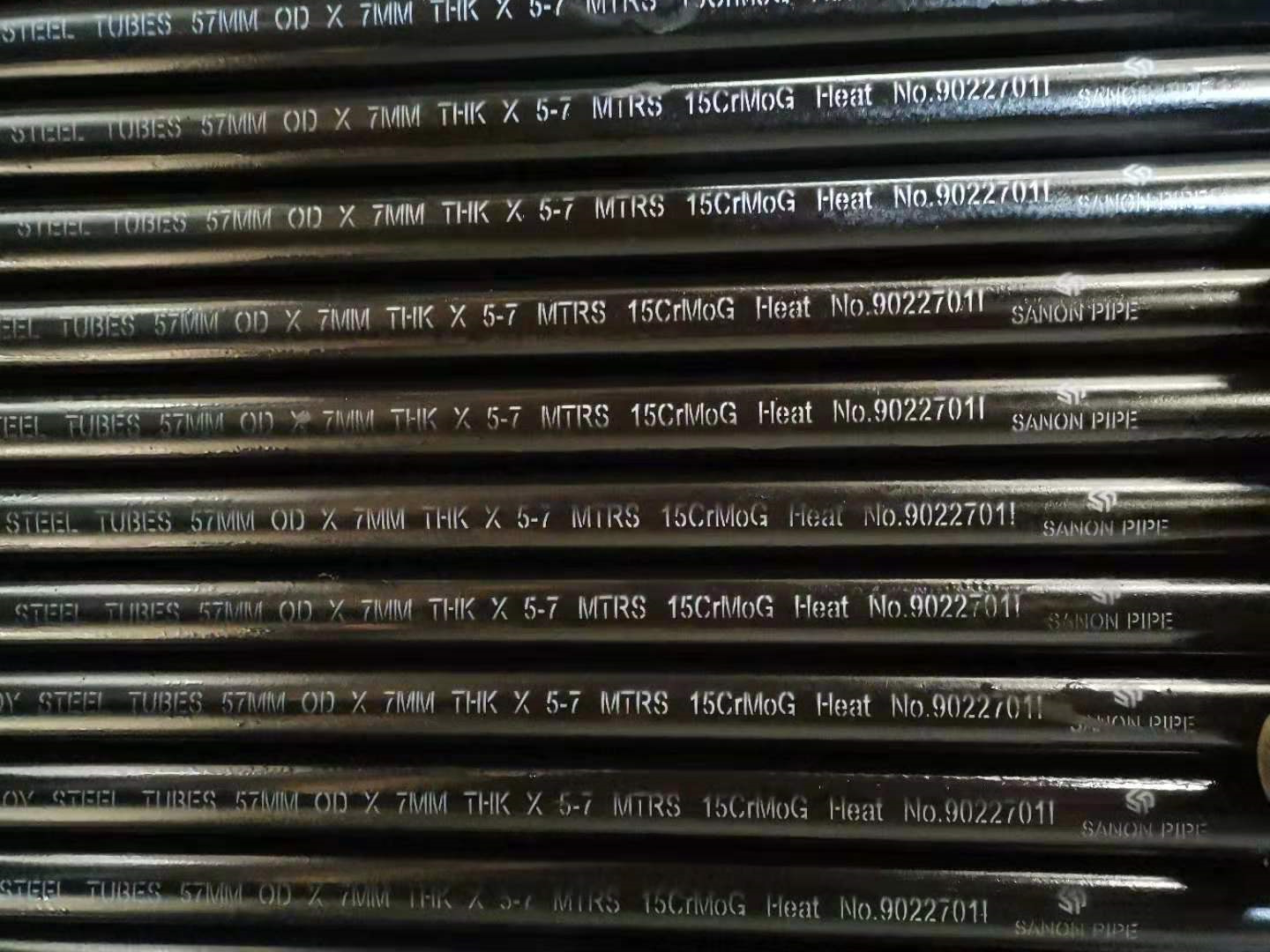

Alloy steel qauv:15 MOG, 20 MOG, 12 CrMoG, 15 CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB

Stainless hlau thiab kub-resistant hlau: 1Cr18Ni9, 1Cr18Ni11Nb

2. Core kev ua tau zoo

Kev kub siab ua haujlwm: Haum rau cov txheej txheem kub xws li roj av tawg (txog 600 ° C lossis ntau dua).

Kev kub siab tsis kam: Cov ntaub ntawv muaj zog ua kom muaj kev nyab xeeb ntawm cov kav dej hauv qab qhov chaw siab.

Corrosion resistance: Cov khoom siv tshwj xeeb alloy zoo tiv thaiv corrosive media xws li hydrogen sulfide thiab carbon dioxide.

Kev ntseeg siab: Kev tswj xyuas nruj kom ntseeg tau tias cov khoom siv kho tshuab thiab tshuaj lom neeg muaj pes tsawg leeg ntawm cov kav hlau ua tau raws li tus qauv GB / T9948.

3. Cov txheej txheem tsim khoom

GB / T9948-2013 seamless steel kav yog tsim los ntawm kub dov thiab txias kos duab (dov):

Kub dov txheej txheem: round tube billet → cua sov → perforation → dov → sizing → txias → straightening → zoo soj ntsuam → cia.

Kev kos duab txias (dov) txheej txheem: perforation → pickling → txias kos duab → tshav kub kho → straightening → flaw detection → marking → cia.

Ob txoj kev ua kom muaj qhov tseeb qhov tseeb, du nto thiab zoo heev txhua yam khoom ntawm cov kav hlau.

4. Daim ntawv thov teb

GB / T9948 roj av cracking kav yog dav siv nyob rau hauv:

Petrochemical kev lag luam: cracking unit, hydrogenation reactor, catalytic hloov khoom siv

Roj refining kev lag luam: kub kub rauv raj, kub exchangers, high-pressure pipelines

Natural gas kev thauj mus los: corrosion-resistant, high-pressure gas kis pipelines

Boiler manufacturing: fais fab chaw nres tsheb boilers, muaj boiler pipeline systems

5. Kev lag luam zeem muag

Nrog rau kev loj hlob sai ntawm kev lag luam petrochemical hauv tsev thiab kev loj hlob ntawm kev lag luam thoob ntiaj teb kev xav tau, qhov muag ntim ntawm GB / T9948 seamless steel kav txuas ntxiv nce. Nws zoo heev kub tsis kam thiab corrosion kuj ua rau nws nyiam cov yeeb nkab khoom nyob rau hauv lub teb ntawm roj av cracking thiab refining.

6. Kev ceev faj rau kev yuav khoom thiab siv

Kev xaiv cov khoom siv nruj: Xaiv cov khoom tsim nyog GB / T9948 (xws li 12CrMoG, 15CrMoG, thiab lwm yam) raws li kev ua haujlwm (kub, siab, corrosiveness).

Daim ntawv pov thawj zoo: xyuas kom meej tias cov yeeb nkab steel ua tau raws li GB / T9948-2013 tus qauv thiab muab daim ntawv qhia txog kev tshuaj xyuas thib peb.

Kev txhim kho thiab kev saib xyuas: Zam tsis txhob muaj kev puas tsuaj thaum lub sij hawm thauj mus los thiab kev teeb tsa, thiab tsis tu ncua xyuas cov kav xa dej corrosion thiab siab.

GB / T9948-2013 roj av cracking yeeb nkab tau dhau los ua ib qho kev xaiv zoo tshaj plaws rau petrochemical, refining, natural gas thiab lwm yam lag luam vim nws qhov zoo ntawm qhov kub thiab txias tsis kam, siab kub tsis kam thiab corrosion kuj. Xaiv cov khoom tsim nyog (xws li 12CrMoG, 15CrMoG, thiab lwm yam) thiab ua raws li cov qauv nruj me ntsis tuaj yeem ua kom muaj kev nyab xeeb thiab ruaj khov ntawm cov kav dej mus ntev.

Ntsiab lus:#Petroleum tawg yeeb nkab, #GB/T9948, #GB/T9948-2013 seamless steel yeeb nkab, #Petroleum cracking steel yeeb nkab, #12CrMoG, #15CrMoG, # Kub kub thiab kub siab steel yeeb nkab, #Petrochemical pipeline

Post lub sij hawm: Jun-09-2025