I. Product Overview

GB/T9948-2013 seamless steel pipe is a high-quality seamless steel pipe specially used for petroleum cracking process, and is widely used in key equipment such as furnace tubes, heat exchangers and pressure pipes in oil refineries. This standard strictly regulates the material, manufacturing process and performance requirements of steel pipes to ensure their stable operation in high-corrosion, high-temperature and high-pressure environments.

2. Materials and performance

1. Main materials

GB/T9948-2013 seamless steel pipes are made of a variety of high-quality alloy materials, including:

Carbon structural steel: 20G, 20MnG, 25MnG

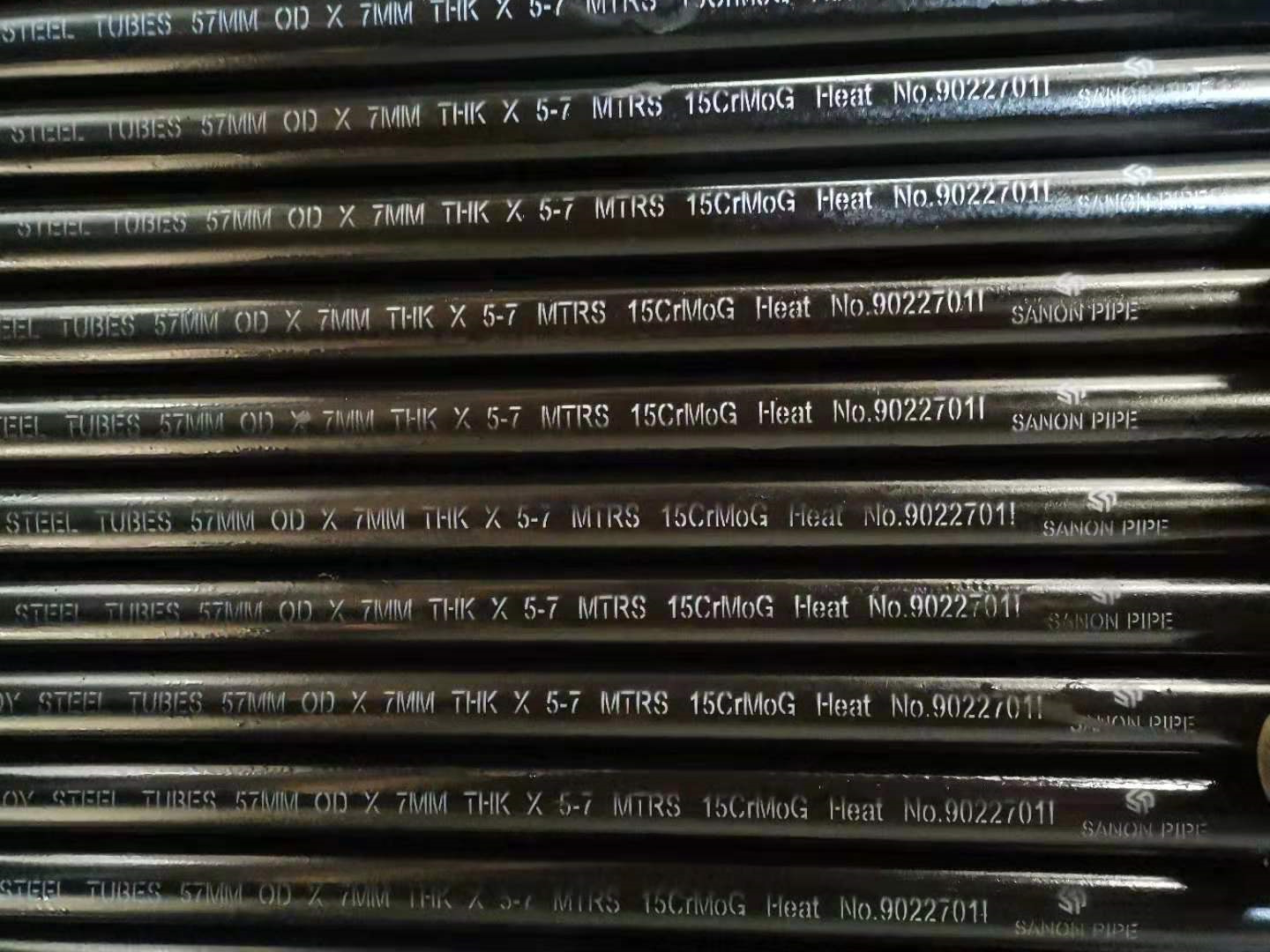

Alloy structural steel: 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB

Stainless steel and heat-resistant steel: 1Cr18Ni9, 1Cr18Ni11Nb

2. Core performance

High temperature resistance: Suitable for high-temperature processes such as petroleum cracking (up to 600°C or more).

High pressure resistance: High-strength materials ensure safe operation of pipelines under high pressure environments.

Corrosion resistance: Special alloy components effectively resist corrosive media such as hydrogen sulfide and carbon dioxide.

High reliability: Strict quality control ensures that the mechanical properties and chemical composition of steel pipes meet the GB/T9948 standard.

3. Manufacturing process

GB/T9948-2013 seamless steel pipes are produced by hot rolling and cold drawing (rolling):

Hot rolling process: round tube billet → heating → perforation → rolling → sizing → cooling → straightening → quality inspection → storage.

Cold drawing (rolling) process: perforation → pickling → cold drawing → heat treatment → straightening → flaw detection → marking → storage.

Both processes ensure high dimensional accuracy, smooth surface and excellent mechanical properties of steel pipes.

4. Application fields

GB/T9948 petroleum cracking pipes are widely used in:

Petrochemical industry: cracking unit, hydrogenation reactor, catalytic reforming equipment

Oil refining industry: high temperature furnace tubes, heat exchangers, high-pressure pipelines

Natural gas transportation: corrosion-resistant, high-pressure gas transmission pipelines

Boiler manufacturing: power station boilers, industrial boiler pipeline systems

5. Market prospects

With the rapid development of the domestic petrochemical industry and the growth of international market demand, the sales volume of GB/T9948 seamless steel pipes continues to rise. Its excellent high temperature resistance and corrosion resistance make it the preferred pipe material in the fields of petroleum cracking and refining.

6. Precautions for purchase and use

Strict material selection: Select the appropriate GB/T9948 material (such as 12CrMoG, 15CrMoG, etc.) according to the working conditions (temperature, pressure, corrosiveness).

Quality certification: Ensure that the steel pipe meets the GB/T9948-2013 standard and provide a third-party inspection report.

Installation and maintenance: Avoid mechanical damage during transportation and installation, and regularly check pipeline corrosion and pressure conditions.

GB/T9948-2013 petroleum cracking pipe has become an ideal choice for petrochemical, refining, natural gas and other industries due to its advantages of high temperature resistance, high pressure resistance and corrosion resistance. Selecting the appropriate material (such as 12CrMoG, 15CrMoG, etc.) and strictly following the standards can ensure the long-term safe and stable operation of the pipeline.

Keywords: #Petroleum cracking pipe, #GB/T9948, #GB/T9948-2013 seamless steel pipe, #Petroleum cracking steel pipe, #12CrMoG, #15CrMoG, #High temperature and high pressure steel pipe, #Petrochemical pipeline

Post time: Jun-09-2025