If you want to know more information, like quotation, products, solutions, etc., please contact us online.

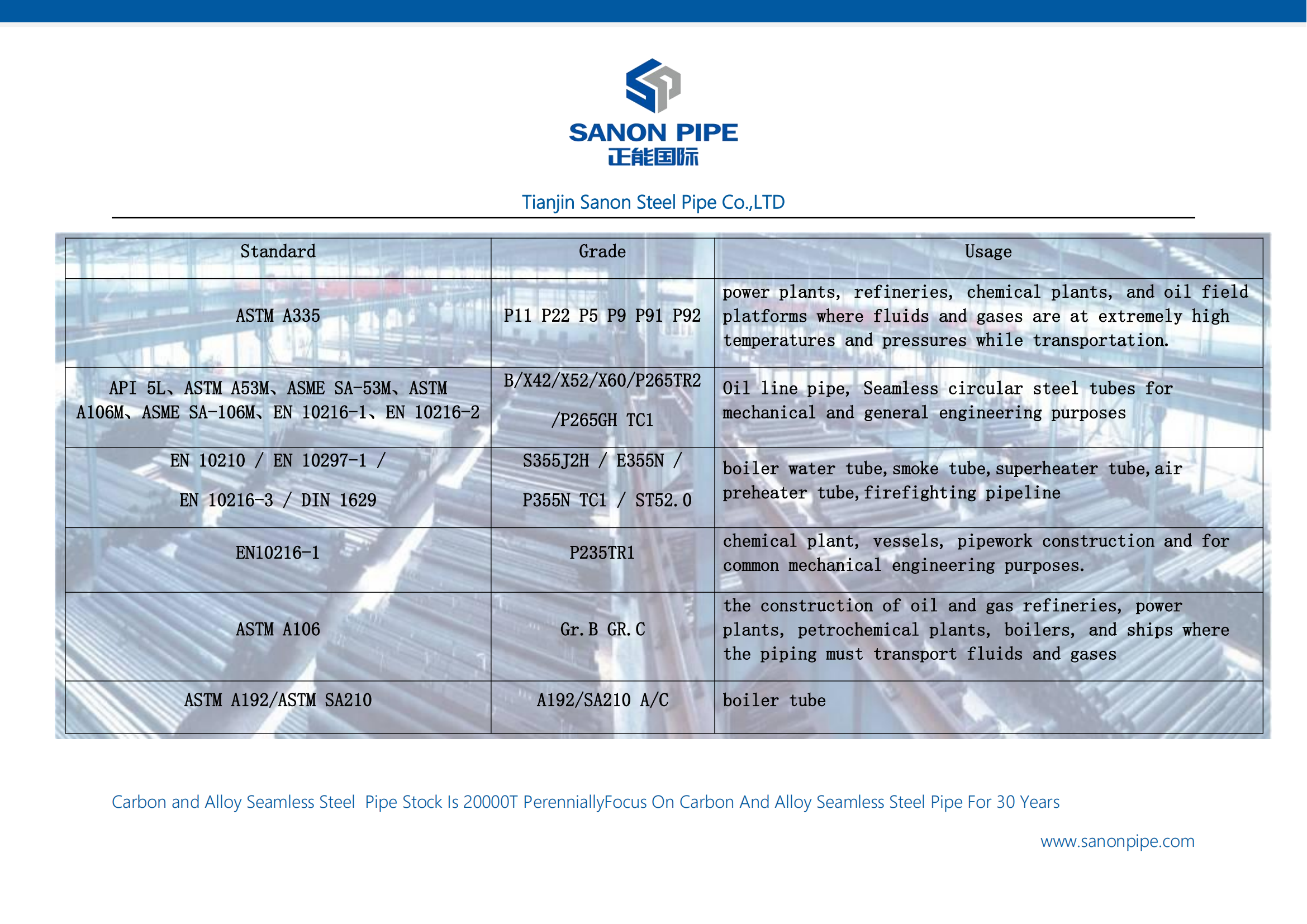

Tianjin Sanon Steel Pipe Co., Ltd. is a stockist. Our stock factory is in Cangzhou City, Hebei Province. Our main sources of goods are boiler pipes, and the representative materials are ASTM A335 P5/P11/P91/P92, ASME SA-106/SA-106M GR.B, GB/T 3087-2008 10#/20#. The representative materials of pipeline pipes are API 5L, API 5CT, the representative materials of petroleum cracking pipes GB/T 9948 are 15MoG/12CrMoVG. GB/T 6479-2013 represents the material 10#/20#, heat exchanger tubes SA179/SA210/SA192, etc., mechanical tubes GB/T 8162 represent the material 10#/20#/Q345/42CrMo, EN10210 represents the material S355JOH/S355J2H, gas cylinder tubes GB1 8248, represent the material 34CrMo4/30CrMo.

India, as one of the world's fastest-growing economies, has a booming boiler manufacturing sector driven by its escalating power demands and industrial expansion. This industry is dominated by a few giants that supply critical equipment to core sectors like power generation, petrochemicals, and fertilizers. In the construction of these boilers, chrome-molybdenum alloy steel pipes conforming to the ASTM A335 standard are indispensable "lifelines." Their consumption level is a direct indicator of the industry's vitality and technical prowess.

Leading Boiler Manufacturers in India

1.Bharat Heavy Electricals Limited (BHEL)

A state-owned enterprise and the undisputed leader in India's power equipment sector, BHEL manufactures a wide range of boilers, from small industrial units to massive ones for supercritical and ultra-supercritical power plants. With projects across India and the globe, BHEL's demand for high-quality materials is immense.

2.A leading energy and environment solutions provider, Thermax is renowned for its highly efficient and clean boiler systems. Its product portfolio includes coal-fired, gas-fired, biomass-fired, and waste heat recovery boilers, serving diverse industrial sectors.

3.Larsen & Toubro (L&T) - Boiler Division

As one of India's largest engineering and construction conglomerates, L&T's boiler division holds a significant position in the large-scale utility and industrial boiler market. Its strong engineering capabilities and execution of mega-projects make it a key player.

4.Cethar Vessels Limited

A specialized boiler manufacturer, Cethar Vessels has a strong reputation in the Indian power sector, particularly for medium to large utility boilers.

Application and Consumption of A335 Alloy Steel Pipes

1. Why A335 Pipes?

Alloy steel pipes under the A335 standard (commonly known as grades like P91, P92, P11, P22) are extensively used in critical sections of boilers due to their excellent high-temperature strength, creep resistance, and oxidation resistance. Key applications include:

Superheaters: Where saturated steam is heated to superheated steam, exposing the pipes to the highest temperatures.

Reheaters: Which reheat steam after it has done work in the turbine to enhance efficiency.

Main Steam Pipes: Transporting high-temperature, high-pressure steam from the boiler to the turbine.

2. Analysis of Consumption Patterns

The consumption of A335 alloy steel pipes by Indian boiler manufacturers is substantial and exhibits the following characteristics:

Directly Proportional to Project Scale and Grade: A large supercritical power plant boiler (e.g., a 660 MW unit) may require hundreds or even thousands of tonnes of A335 P91/P92 pipes. In contrast, a small industrial boiler might use only a few tonnes.

Increasing Use of High-Grade Materials: As India shifts towards more efficient, lower-emission supercritical and ultra-supercritical technologies, the demand for high-performance grades like A335 P91 and P92 is growing rapidly. These materials allow for higher steam parameters (temperature and pressure), thereby increasing plant efficiency.

Dependence on Both Imports and Domestic Production: Some Indian steel companies (e.g., ISMT) can produce certain A335 grades (like P11, P22). However, for the most technically demanding grades like P91 and P92, there remains a degree of reliance on imports from China, Europe, and Japan due to quality and capacity considerations. This makes supply chain management and cost control a key challenge for boiler makers.

Market Demand Volatility: Consumption is closely tied to India's power investment cycles. Demand for A335 pipes surges during periods of strong government push for coal-fired power capacity addition or robust industrial investment.

India's leading boiler manufacturers, such as BHEL, Thermax, and L&T, are key players in the global boiler market. Their growth is intrinsically linked to the energy future of India and the world. A335 alloy steel pipes, as a critical material for their core products, see consumption that is not just a metric of these companies' business scale but also a barometer for India's industrial infrastructure development and technological advancement. Looking ahead, the pursuit of high-efficiency, clean energy technologies is expected to drive continued growth in the demand for high-performance A335 grade pipes.

Post time: Sep-26-2025