I-15Mo3 (15MoG) : Ingumbhobho wensimbi kwi-DIN17175 standard. Yityhubhu yentsimbi ye-carbon molybdenum enedayamitha encinci yebhoyila kunye ne-superheater, kunye ne-pearlescent yohlobo lwentsimbi eshushu. Ngo-1995, yatshintshwa ukuba ibeGB5310kwaye yabizwa ngokuba yi-15MoG. Ukubunjwa kwayo kweekhemikhali kulula, kodwa iqulethe i-molybdenum, ngoko inamandla angcono e-thermal kune-carbon steel ngelixa igcina ukusebenza kwenkqubo efanayo njenge-carbon steel. Ngenxa yokusebenza kwayo kakuhle, ixabiso eliphantsi, lisetyenziswa kakhulu ehlabathini. Nangona kunjalo, insimbi inomkhuba wokwenza i-graphitization emva kokusebenza kwexesha elide kwiqondo lokushisa eliphezulu, ngoko ukushisa kwayo kufuneka kulawulwe ngaphantsi kwe-510 ℃, kwaye inani le-Al elongezelelweyo kwi-smelting kufuneka lilinganiselwe ukulawula nokulibazisa inkqubo ye-graphitization. Le ityhubhu yentsimbi isetyenziselwa ikakhulu ubushushu obuphantsi be-superheater kunye ne-reheater ephantsi yobushushu. Ubushushu bodonga bungaphantsi kwe-510℃. Ukubunjwa kwayo kweekhemikhali C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Umgangatho wamandla oqhelekileyo σs≥270-285, σb≥450-600 MPa; Plastic delta 22 okanye ngaphezulu.

15CrMoG:GB5310-95 insimbi (ehambelana ne-1CR-1 / 2Mo kunye ne-11 / 4CR-1 / 2MO-Si insimbi esetyenziswa kakhulu kwihlabathi), umxholo wayo we-chromium uphezulu kunentsimbi ye-12CrMo, ngoko inamandla aphezulu e-thermal kwi-500-550 ℃. Xa ubushushu budlula i-550℃, amandla e-thermal ensimbi ayancipha kakhulu. Xa isetyenziswa ixesha elide kwi-500-550 ℃, i-graphitization ayenzeki, kodwa i-carbide spheroidization kunye ne-alloying element redistribution zenzeka, ezikhokelela ekunciphiseni amandla e-thermal yentsimbi. Intsimbi inokumelana kakuhle nokuphumla kwi-450 ℃. Ukwenza umbhobho wayo kunye nokusebenza kwenkqubo ye-welding kulungile. Isetyenziswa ikakhulu njengoxinzelelo oluphezulu kunye oluphakathi kombhobho womphunga kunye nebhokisi yokudibanisa kunye neparameter yomphunga ngaphantsi kwe-550 ℃, ityhubhu ye-superheater enobushushu bodonga obungaphantsi kwe-560 ℃, njl njl. CR0.80-1.10, MO0.40-0.55; Ngaphantsi kwemeko eqhelekileyo yokucaphuka, inqanaba lamandla σs≥235, σb≥440-640 MPa; Idelta yeplastiki p 21.

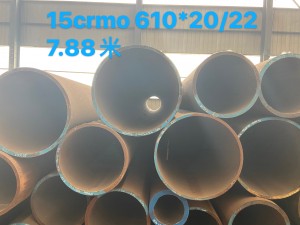

T22 (P22), 12Cr2MoG: T22 (P22) ziASME SA213 (SA335) izixhobo zekhowudi, ezifakwe kuyoGB5310-95. Kwi-series ye-CR-Mo yensimbi, ukusebenza kwayo kwamandla e-thermal kuphezulu, ubushushu obufanayo bomelele kunye noxinzelelo oluvumelekileyo kune-9CR-1Mo yentsimbi nangaphezulu, ngoko isetyenziswa ngokubanzi kumandla angaphandle ashushu, amandla enyukliya kunye neenqanawa zoxinzelelo. Nangona kunjalo, uqoqosho lwayo lobuchwephesha lungaphantsi kwe-12Cr1MoV yethu, ngoko ke ayisetyenziswanga kangako kwimveliso yebhoyila yamandla ashushu asekhaya. Sebenzisa kuphela xa kuyimfuneko (ingakumbi xa uyilwe kwaye usenziwa ngokuhambelana nekhowudi ye-ASME). Intsimbi ayinaluvelwano kunyango lobushushu kwaye ineplastiki ephezulu ehlala ixesha elide kunye nokusebenza kakuhle kwe-welding. Ityhubhu ye-T22 encinci yedayamitha isetyenziswa ikakhulu njengobushushu bodonga lwentsimbi ngaphantsi kwe-580 ℃ i-superheater kunye ne-reheater yomphezulu ityhubhu yokufudumeza, njl.P22ityhubhu enkulu yedayamitha isetyenziswa ikakhulu kubushushu bodonga lwentsimbi ayikho ngaphezulu kwe-565 ℃ ibhokisi yokudibanisa i-superheater/reheater kunye nombhobho ophambili womphunga. Ukubunjwa kwayo kweekhemikhali C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; Ngaphantsi kwemeko eqhelekileyo yokucaphuka, inqanaba lamandla σs≥280, σb≥450-600 MPa; Plastic delta 20 okanye ngaphezulu.

12Cr1MoVG:GB5310-95 nano standard steel, luxinzelelo oluphezulu lwasekhaya, uxinzelelo oluphezulu lwe-Ultra, i-subcritical power plant boiler boiler superheater, ibhokisi yokuqokelela kunye ne-conduit engundoqo esetyenziswa kakhulu yintsimbi. Ukubunjwa kweekhemikhali kunye neepropati zemishini ye-12Cr1MoV plate iyafana. Ukubunjwa kwayo kweekhemikhali kulula, umxholo we-alloy we-alloy ungaphantsi kwe-2%, kwikhabhoni ephantsi, i-alloy ephantsi ye-pearlescent yentsimbi yentsimbi eshushu. I-Vanadium ingenza i-carbide ezinzileyo ye-VC kunye nekhabhoni, enokwenza i-chromium kunye ne-molybdenum kwintsimbi ekhethwayo ikhona kwi-ferrite, kwaye icothise isantya sokudluliselwa kwe-chromium kunye ne-molybdenum ukusuka kwi-ferrite ukuya kwi-carbide, ukuze intsimbi izinzile kwiqondo lokushisa eliphezulu. Isixa esipheleleyo sezinto ezidibeneyo kule ntsimbi sisiqingatha kuphela se-2.25 CR-1Mo yensimbi esetyenziswa ngokubanzi ngaphandle, kodwa amandla ahlala e-580 ℃ kunye ne-100,000 h yi-40% ephezulu kuneyokugqibela. Ngaphezu koko, inkqubo yokuvelisa ilula kwaye ukusebenza kwe-welding kulungile. Ngethuba nje inkqubo yonyango lokushisa ingqongqo, ukusebenza okubanzi kunye nokusebenza kwamandla okushisa kunokwaneliswa. Owona msebenzi wesikhululo samandla ubonisa ukuba umbhobho ongundoqo we-12Cr1MoV usenokusetyenziswa emva kokusebenza ngokukhuselekileyo kwi-540℃ iiyure eziyi-100,000. Ityhubhu enobubanzi obukhulu isetyenziswa ikakhulu njengebhokisi yokuqokelela kunye nombhobho ophambili weparamitha yomphunga ongaphantsi kwe-565 ℃, kwaye ityhubhu enobubanzi obuncinci isetyenziselwa ityhubhu yokufudumeza umphezulu webhoyila yobushushu bodonga lwentsimbi ngaphantsi kwe-580 ℃.

I-12Cr2MoWVTiB (G102) :Gb5310-95 kwintsimbi, uphuhliso China ngokwakhe kwiminyaka yoo-1960, ikhabhoni ephantsi, ingxubevange ephantsi (isixa esincinci seyantlukwano) Uhlobo lwentsimbi ye-Bainite yamandla ashushu, ukusuka kwiminyaka yoo-1970 yaqukwa kwiSebe leMetallurgical Industry standard YB529-70 kwaye ngoku umgangatho wesizwe, ekupheleni kwe-1980 i-Industry of the Ministry of Metallurgication of the Ministry of Metallurgical Ministry of the Ministry of Metallurgical power the Ministry of Metallurgica ukuchongwa ngokubambisana. Intsimbi ineempawu ezilungileyo ezibanzi zoomatshini, kwaye amandla ayo obushushu kunye nobushushu benkonzo buphezulu kunezo zentsimbi ezifanayo phesheya, zifikelela kwinqanaba leentsimbi ze-chromium-nickel austenitic kwi-620 ℃. Oku kungenxa yokuba intsimbi iqulethe iindidi ezininzi zezinto ezixutywayo, kwaye yongezwa kwakhona ukuphucula ukuxhathisa i-oxidation yezinto ezifana ne-Cr, i-Si, ngoko ke ubushushu benkonzo ephezulu bunokufikelela kuma-620 ℃. Ukusebenza kwangempela kwesikhululo samandla kubonisa ukuba isakhiwo kunye neempawu zombhobho wensimbi azitshintshi kakhulu emva kokusebenza kwexesha elide. Isetyenziswa ikakhulu njengetyhubhu ye-superheater kunye netyhubhu yokufudumeza kwibhoyila yeparameter ephezulu kakhulu enobushushu bentsimbi ≤620℃. Ukubunjwa kwayo kweekhemikhali C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42, 0.050.0. B0.002-0.008; Ngaphantsi kwemeko eqhelekileyo yokucaphuka, inqanaba lamandla σs≥345, σb≥540-735 MPa; Idelta yeplastiki p 18.

Sa-213t91 (335P91) : Inombolo yentsimbi ngaphakathiI-ASME SA-213(335) umgangatho. Iphuhliswa yiRubber Ridge National Laboratory yaseUnited States of America, esetyenziswa kumandla enyukliya (inokusetyenziswa nakweminye imiba) amacandelo obushushu obuphezulu bezinto eziphathekayo, intsimbi isekelwe kwi-T9 (9CR-1MO) yentsimbi, kumda womxholo wekhabhoni, ukulawula ngokungqongqo umxholo we-P kunye no-S kunye nezinye izinto ezishiyekileyo ngaxeshanye, Uhlobo olutsha lwe-ferritic steelresistant luyilwe kwisixa-mali se-ferritic yokufudumala. 0.030-0.070% N, 0.18-0.25% V kunye ne-0.06-0.10% Nb ukuhlangabezana neemfuno zokucocwa kweenkozo. YiI-ASME SA-213intsimbi esemgangathweni yekholamu, eyatshintshwa yafakwaGB5310umgangatho ngo-1995 kwaye ibakala yi-10Cr9Mo1VNb. Umgangatho wamazwe ngamazwe ISO/ DIS9399-2 udweliswe njenge X10 CRMOVNB9-1.

Ngenxa yomxholo wayo ophezulu we-chromium (9%), ukuxhathisa kwe-oxidation, ukumelana nokugqwala, amandla okushisa aphezulu kunye nokuthambekela kwe-non-graphitization kungcono kunezo zentsimbi ephantsi. I-Molybdenum (1%) iphucula ubukhulu becala amandla obushushu obuphezulu kwaye inqanda ukuthambekela okushushu kwentsimbi yechromium. Xa kuthelekiswa ne-T9, i-welding kunye neempawu zokudinwa kwe-thermal ziphuculwe, amandla ahlala kwi-600 ℃ aphindwe kathathu kulawo wokugqibela, kunye ne-high-temperature resistant corrosion resistance ye-T9 (9CR-1Mo) yensimbi igcinwa. Xa kuthelekiswa ne-austenitic stainless steel, i-coefficient yokwandisa incinci, i-thermal conductivity ilungile, kwaye inamandla ahlala ehlala phezulu (afana ne-TP304 austenitic steel ratio, de ubushushu obuqinileyo yi-625 ℃, ubushushu obulinganayo boxinzelelo yi-607 ℃). Ke ngoko, ineepropathi ezibanzi ezibanzi zoomatshini, ubume obuzinzile kunye neepropathi ngaphambi nangemva kokuguga, i-welding elungileyo kunye nepropathi yenkqubo, amandla ahlala ixesha elide kunye nokumelana ne-oxidation. Isetyenziswa ikakhulu kwi-superheater kunye ne-reheater kunye nobushushu bentsimbi ≤650℃ kwibhoyila. Ukubunjwa kwayo kweekhemikhali C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, Al≤0.04, N0. N0.03-0.07; Ngaphantsi kwemeko eqhelekileyo yokucaphuka, inqanaba lamandla σs≥415, σb≥585 MPa; Plastic delta 20 okanye ngaphezulu.

Ixesha lokuposa: Sep-07-2022